Biochar Kiln Revolution: The High-Efficiency Rotary Kiln Biochar Production Syste

Dec 05, 2025

Biochar Kiln Revolution: The High-Efficiency Rotary Kiln Biochar Production Syste

PyroGreen Energy Technology Co., Ltd. is a technology enterprise specializing in green renewable energy, green chemical engineering, and energy conservation and environmental protection. Our expertise encompasses advanced biochar production equipment, including our core innovation: a rotary kiln biochar carbonization system based on internal indirect heating technology. This system represents a leap forward in efficient and controllable thermochemical conversion.

What is Biochar?

Biochar is a carbon-rich solid material made through a thermochemical conversion process. The essence of its preparation is to pyrolyze organic biomass at high temperatures in an oxygen-limited or oxygen-free environment, thereby stabilizing carbon.

Soil Functions and Benefits of Biochar

| Functional Categories |

Brief Introduction of Scientific Mechanisms and Effects |

| Carbon Sequestration & Stabilization |

The pyrolysis process reorganizes unstable organic carbon into highly aromatic stable structures, significantly extending its residence time in the soil |

| Soil Physical Improvement |

The developed porous structure helps reduce soil bulk density and increase porosity, enhancing water-holding capacity and aeration. |

| Soil Chemical Improvement |

Rich surface functional groups and huge specific surface area provide strong ion exchange and adsorption capabilities, improving soil fertility retention. |

| Soil Biological Promotion |

The porous structure provides habitat and physical protection for soil microorganisms, promoting diversity and activity.

|

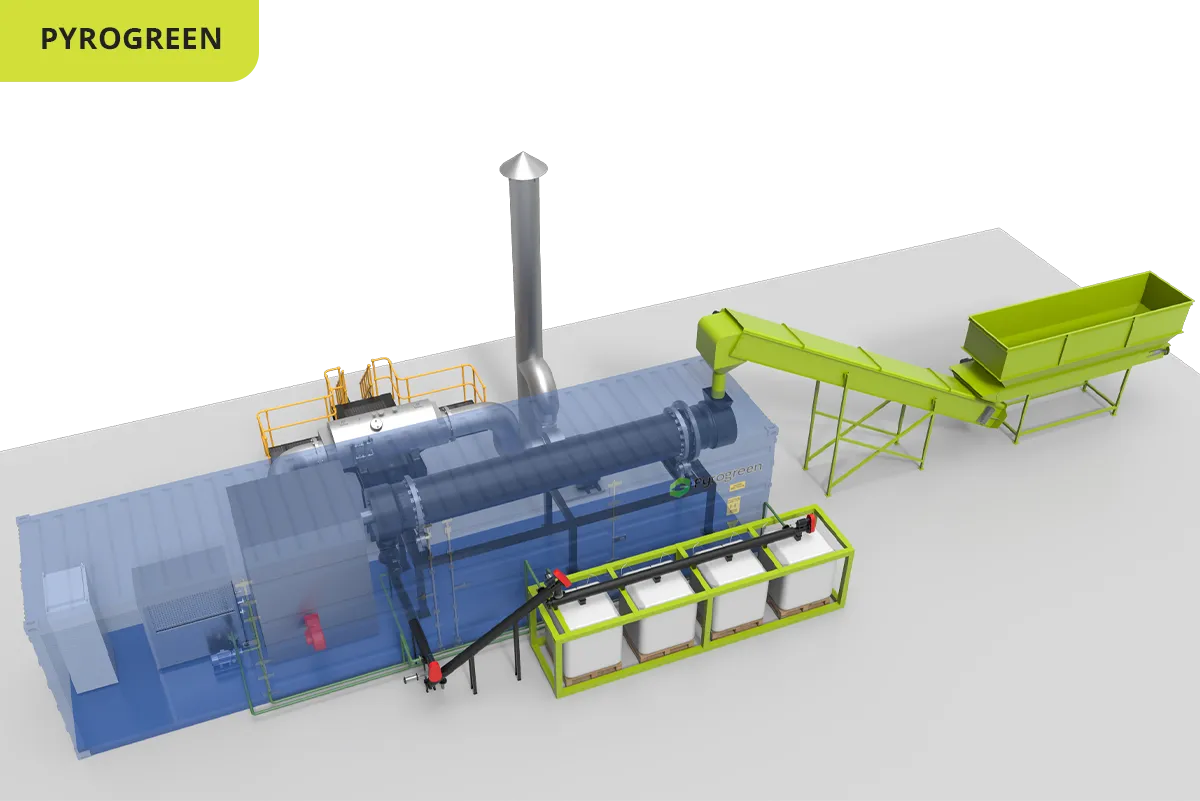

Core Technology: The Rotary Kiln Indirect Pyrolysis System

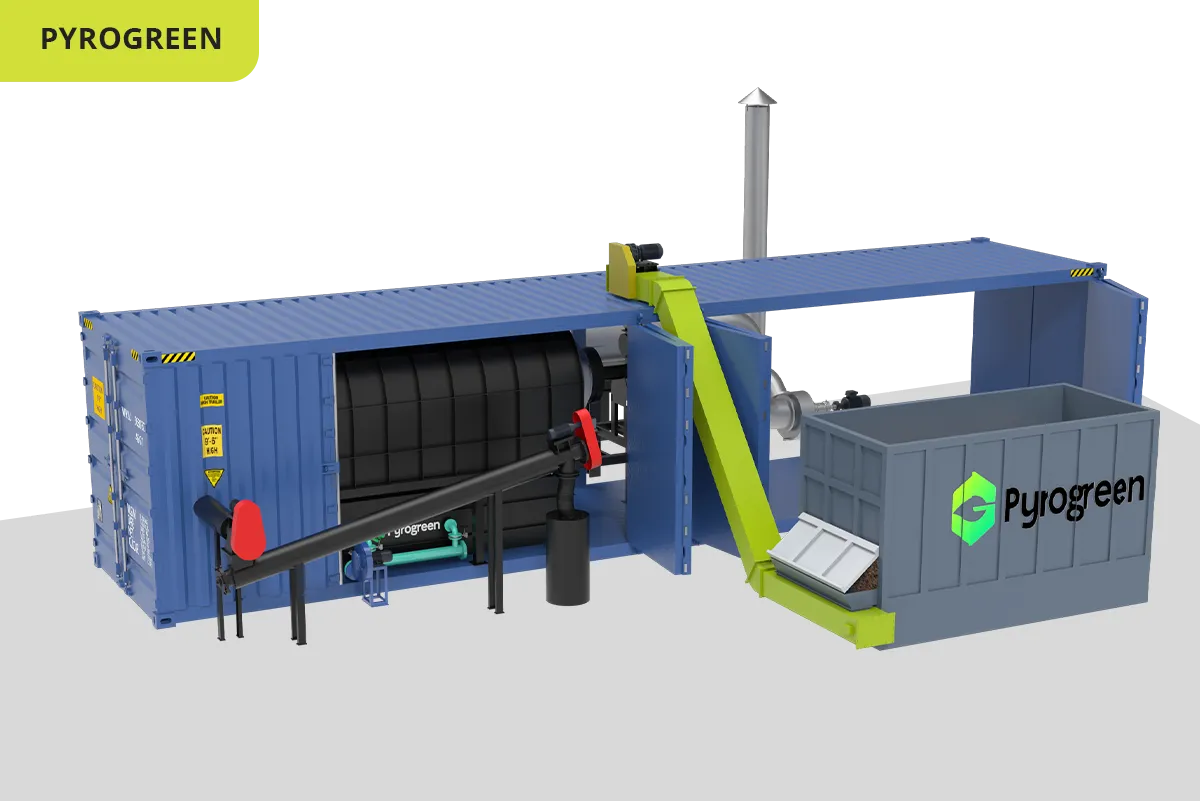

Our flagship biochar kiln solution is an indirect-heating rotary kiln biochar production system. This continuous rotary kiln is engineered for efficiency, consistency, and environmental performance, making it premier biochar production equipment.

|

|

| Rotary Kiln Carbonization/Torrefaction System | Rotary Kiln Carbonization System(Inner Indirect Heating) |

Advantages of Our Rotary Kiln Design

The rotary kiln design is central to our system's performance. As a biomass rotary kiln, it operates on distinct technical principles:

| Indirect Heating Method: | Heat is transferred through the rotating kiln wall, preventing direct contact between biomass and flame. This ensures precise temperature control and uniform heat distribution. |

| Anoxic Environment Control: | The sealed rotary kiln design maintains the necessary oxygen-free atmosphere, maximizing solid carbon yield. |

| Continuous & Controllable Process: | The continuous rotary kiln motion allows for constant flipping and advancement of material. Coupled with precise control over temperature and residence time, it guarantees consistent product quality. |

| Environmentally Friendly Operation: | The closed system allows pyrolysis gases to be recycled for process heating, enabling energy circulation and controlled emissions. |

Biochar Rotary Kiln Unit for sale

We offer a range of standardized rotary kiln models to suit various scales:

| Small/Medium Units: | Ideal for distributed production at farms or community scales. |

| Large Integrated Systems: | Designed for regional biomass centers or industrial biochar kiln production lines. |

| System Processing Power and Output | Our biomass rotary kiln is designed to process diverse agricultural and forestry residues. Under standard conditions, it efficiently converts biomass into stable biochar, with yield depending on feedstock and process parameters. |

The Scientific Pyrolysis Process

| Drying & Preheating: | Biomass absorbs heat, removing moisture. |

| Pyrolysis & Carbonization: | Under oxygen-limited, moderate-high temperature conditions within the rotary kiln, organic components (cellulose, hemicellulose, lignin) undergo chemical breakdown and recombination, forming a solid carbon skeleton. |

| Cooling & Stabilization: | The hot biochar is cooled under controlled conditions to become a stable final product. |

Featured Carbon Asset Projects

Discover our global carbon asset development initiatives that combine biochar production with renewable energy solutions, delivering both environmental impact and financial returns.

|

|

Carbon Asset Project #1Malaysia - 2MW Biomass (EFB) Gasification Heat Supply

Partially Operational - Carbon Credit Registration in Progress

This Malaysian biomass gasification heat supply project utilizes one set of Powermax®TFBG equipment. The syngas replaces diesel in diesel boilers for heating, with high-quality biochar as a byproduct for agricultural applications. Biomass Feedstock:EFB briquettes, ~57.6 tons/day

Annual Biochar Yield:~1,920 tons

CO₂ Sequestration:2,970.88 tons

Carbon Credit Projections

Estimated Annual Carbon Credits:~1,500 tons

Estimated Annual Revenue:~$225,000

|

Carbon Asset Project #2Malaysia - 3MW Biomass Gasification Power Generation

Partially Operational - Carbon Credit Registration in Progress

This 3MW Malaysian biomass gasification power generation project utilizes two sets of Powermax®TFBG equipment. The syngas is used for electricity generation, with high-quality biochar as a byproduct for agricultural applications. Biomass Feedstock:Wood chips, ~77.6 tons/day

Annual Biochar Yield:~2,586 tons

CO₂ Sequestration:7,301.14 tons

Carbon Credit Projections

Estimated Annual Carbon Credits:~3,600 tons

Estimated Annual Revenue:~$540,000

|

|

|

Carbon Asset Project #3Myanmar - 12MW Biomass Gasification Power Plant

Partially Operational - Carbon Credit Registration in Progress

This Myanmar biomass gasification power plant utilizes twelve sets of Powermax®DFBG equipment. The syngas is used for electricity generation, with high-quality biochar as a byproduct for fishery feed and agricultural applications. Biomass Feedstock:Rice husk, ~518.4 tons/day

Annual Biochar Yield:~51,840 tons

CO₂ Sequestration:93,139.2 tons

Carbon Credit Projections

Estimated Annual Carbon Credits:~45,000 tons

Estimated Annual Revenue:~$6,750,000

|

Carbon Asset Project #4Indonesia - 1MW Biomass Gasification Power Plant

Fully Operational - Carbon Credit Registration in Progress

This Indonesian biomass gasification power plant utilizes two sets of Biowatt 500 equipment. The syngas is used for electricity generation, with high-quality biochar as a byproduct for agricultural applications. Biomass Feedstock:Coconut shell/wood chips, ~28.8 tons/day

Annual Biochar Yield:~768 tons

CO₂ Sequestration:1,484 - 2,168 tons

Carbon Credit Projections

Estimated Annual Carbon Credits:500 - 1,000 tons

Estimated Annual Revenue:$75,000 - $150,000

|

Summary of Biochar's Application Value

Biochar is an engineered material for soil improvement and environmental management. Its multidimensional value includes:

| Agricultural Sustainability: | Enhances soil properties to improve fertility and resilience, reducing dependence on external inputs. |

| Climate Change Mitigation: | A carbon-negative technology that sequesters atmospheric CO₂ into a stable form for long-term soil storage. |

| Waste Recycling: | Provides a high-value path for transforming organic waste, promoting a circular economy. |

Discover Our Rotary Kiln for Sale

For those seeking advanced, industrial-scale solutions, our high-performance rotary kiln for sale embodies optimal rotary kiln design for reliable biochar production. Contact us to learn more about our continuous rotary kiln systems and how they can benefit your operations.