Optimizing Large-Scale Biochar Production: A Guide to Commercial Biochar Kiln Systems

Dec 03, 2025

Optimizing Large-Scale Biochar Production: A Guide to Commercial Biochar Kiln Systems

| Contact Us |

A Commercial Biochar Kiln is the core pyrolysis system for large scale biochar production. Unlike small-scale units, it is engineered for efficient, continuous, and high-volume conversion of biomass into high-quality biochar. This process transforms agricultural and forestry residues—such as wood chips, rice husks, coconut shells, and more—into a stable, carbon-rich solid under precisely controlled, oxygen-limited conditions. For effective commercial biochar production, selecting the right technology is paramount.

|

|

|

|

Core Technology: The Industrial Rotary Kiln for Biochar

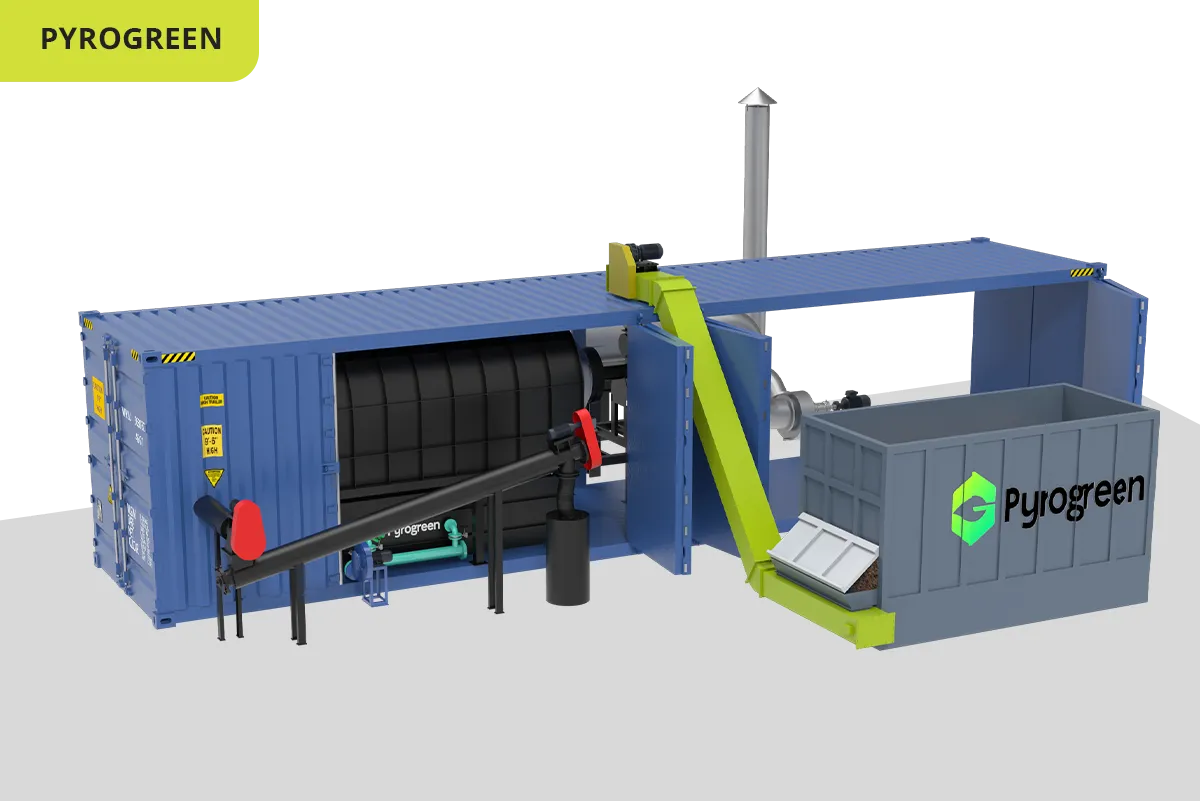

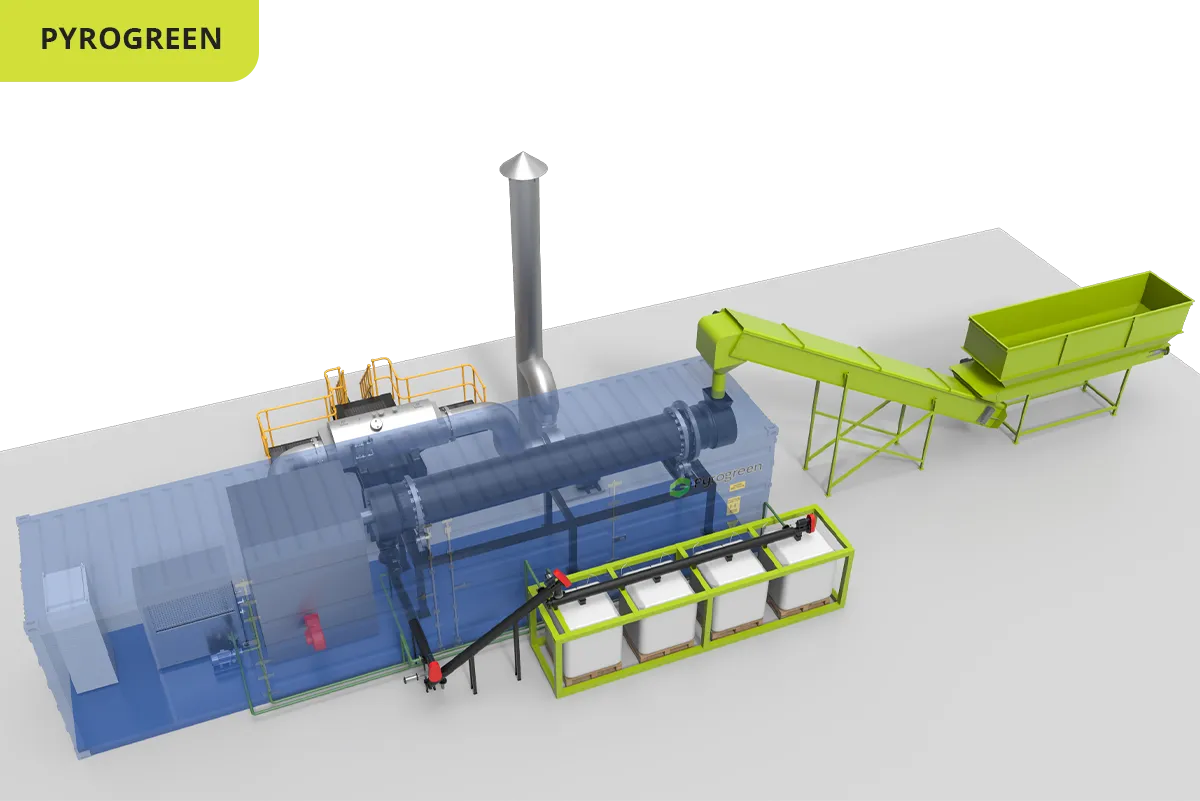

Pyrogreen, as a leading rotary kiln manufacturer, provides integrated solutions for biochar production plants. The industrial rotary kiln, specifically the rotary drum kiln, is a proven technology for continuous biochar production due to its efficiency, reliability, and scalability.

Advantages of the Rotary Kiln System

The rotary kiln system excels in large-scale biochar manufacturing for several reasons:

| Continuous Processing: | Enables steady feeding, pyrolysis, and discharge, ideal for plant-level output. |

| Superior Heat Transfer: | The rotating cylinder ensures uniform mixing and contact, maximizing thermal efficiency and throughput. |

| Process Control: | Provides precise management of temperature and material residence time. |

Superior Product Quality with an Indirect Fired Rotary Kiln

For premium output, Pyrogreen's indirect fired rotary kiln (also called an indirect rotary kiln or rotary retort furnace) is the optimal choice.

| Pure Pyrolysis Atmosphere: | The heat source is completely separated from the processing chamber. This isolation ensures precise control over the biochar manufacturing process, preventing product oxidation and maximizing fixed carbon yield. |

| High-Purity Biochar: | Combustion gases do not contact the biomass, resulting in a cleaner, uncontaminated final product. |

| Energy Efficiency: |

Syngas from pyrolysis can be recycled to fuel the system, significantly improving the rotary kiln biochar production cost and operational sustainability. |

The Integrated Biochar Production Process

As a professional rotary kiln manufacturer, Pyrogreen provides a complete, automated rotary kiln system designed for efficient continuous biochar production. Our industrial rotary kiln solution seamlessly integrates all stages from feed to final product, ensuring optimal rotary kiln biochar production cost and output quality.

Industrial Rotary Kiln System for Continuous Biochar Production

|

|

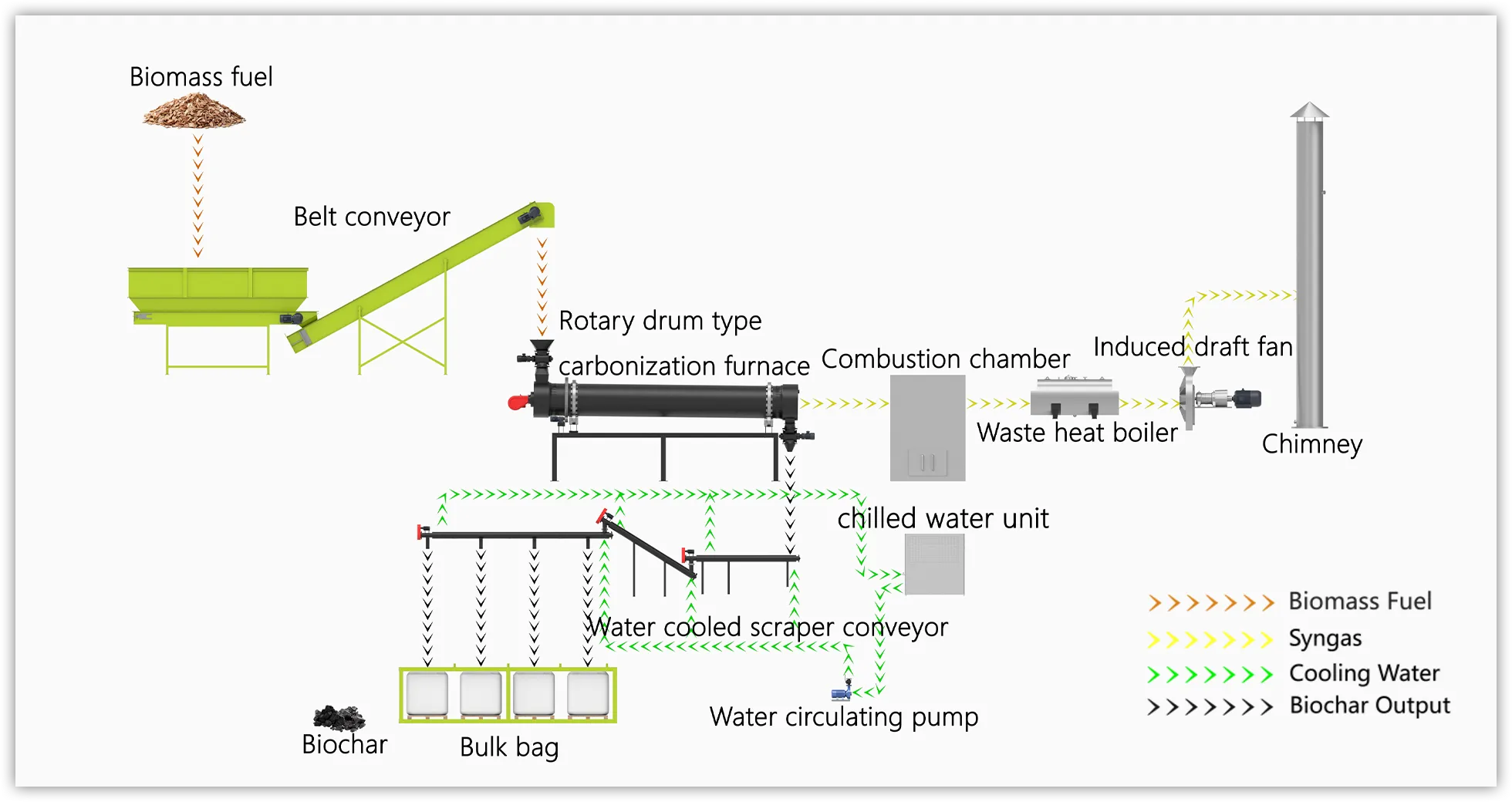

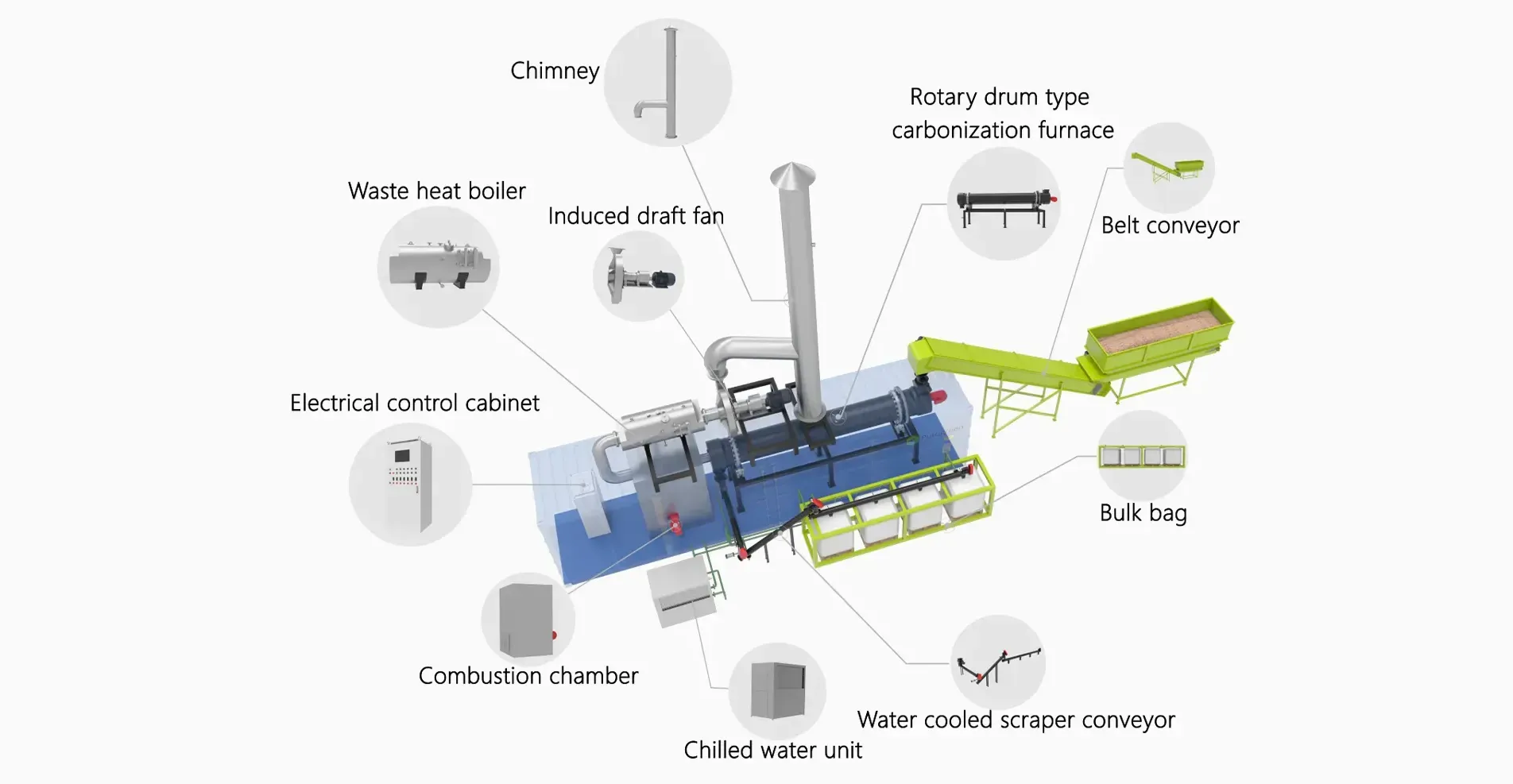

Here is how our system operates:

| Feeding & Conveying: | Prepared biomass is uniformly fed into the core rotary drum kiln via an automated belt conveyor. |

| Core Pyrolysis (Carbonization): | Inside the sealed indirect fired rotary kiln (also known as a rotary retort furnace), biomass is heated under precisely controlled, oxygen-limited conditions. This thermochemical process converts the biomass into high-quality biochar and syngas. |

| Cooling & Collection: | The hot biochar is discharged and rapidly cooled by a water-cooled scraper conveyor (supported by a chilled water unit) to preserve its quality. The finished biochar is then ready for packaging in bulk bags. |

| Energy Recovery & Emission Control: | The syngas produced is channeled to the combustion chamber as a primary fuel source, creating a highly efficient energy loop. Exhaust gases pass through a waste heat boiler for additional energy recovery, are cleaned, and are finally expelled via the chimney by an induced draft fan. The entire process is managed from a centralized electrical control cabinet. |

This closed-loop, automated design is the hallmark of a modern commercial biochar production facility, maximizing resource efficiency and ensuring environmental compliance for large-scale biochar operations.

Solutions for Your Biochar Plant

Whether you are planning a new biochar production plant or scaling up existing operations, understanding the technology is key to making biochar large scale a commercial success.

Exploring Commercial Biochar Kiln for Sale Options

When evaluating a commercial biochar kiln for sale, consider throughput, feedstock flexibility, and automation. Pyrogreen's systems are designed for large scale biochar production, ensuring high thermal efficiency and consistent quality. Our commercial biochar kiln models support fully automated, continuous biochar production to meet industrial demands.

Partnering with Expert Rotary Kiln Suppliers

Choosing the right partner is crucial. As experienced rotary kiln suppliers, we at Pyrogreen offer more than equipment; we deliver a complete rotary kiln system tailored to your specific feedstock and production goals for effective biochar manufacturing.

Technical Specifications: Industrial Rotary Kiln Models

Our range of industrial rotary kiln systems is built for performance and durability in commercial biochar production.

|

Pyrogreen series |

2T |

4T |

6T |

8T |

10T |

|

|

Dimensions |

Diameter (mm) x length (mm) |

⌽ 1200x7500 |

⌽ 1600x7500 |

⌽ 1800x10500 |

⌽ 2000x13000 |

⌽ 2400x13000 |

|

Feed motor power (kW) |

1.1kw |

3kw |

4kw |

7.5kw |

1 1kw |

|

|

Feed screw diameter (mm) |

⌽ 219 |

⌽ 219 |

⌽ 325 |

⌽ 377 |

⌽ 377 |

|

|

Thermometer selection |

Wireless thermometer |

Wireless thermometer |

Wireless thermometer |

Wireless thermometer |

Wireless thermometer |

|

|

Silo |

Level gauge |

Rotary paddle/Weight |

Rotary paddle/Weight |

Rotary paddle/Weight |

Rotary paddle/Weight |

Rotary paddle/Weight |

|

Discharge |

Rotary valve diameter |

⌽ 219 |

⌽ 219 |

⌽ 325 |

⌽ 377 |

⌽ 377 |

|

Cooling |

Cooling system |

Spiral cooler |

Spiral cooler |

Spiral cooler/Plate type slag cooler |

Spiral cooler/Plate type slag cooler |

Spiral cooler/Plate type slag cooler |

|

Rated fuel feed rate (moisture content <18%) |

0.8 |

1.6 |

2.4 |

3.2 |

4 |

|

|

Rated steam output (m3/h) |

1000 |

2000 |

3000 |

4000 |

5000 |

|

|

Note:lf there are any deviations in the above data, please refer to the actual product and market conditions. The core components are all made of 310s |

||||||

(Include your existing specification table here: BRKC600, BRKC1000, Pyrogreen series 2T-10T, etc.)

Key features across all models include PLC control, indirect heating, and a modular design for easier installation—central to an efficient biochar manufacturing process.

Conclusion: Investing in a Biochar Kiln for Sale

Investing in a robust biochar kiln for sale from a reputable rotary kiln manufacturer is the foundation for a viable biochar plant. An indirect fired rotary kiln system offers the control and efficiency required for profitable large scale biochar operations, optimizing both output quality and long-term rotary kiln biochar production cost.

For businesses serious about making biochar large scale, Pyrogreen's commercial biochar kiln technology provides a reliable, advanced pathway to turn biomass into value.