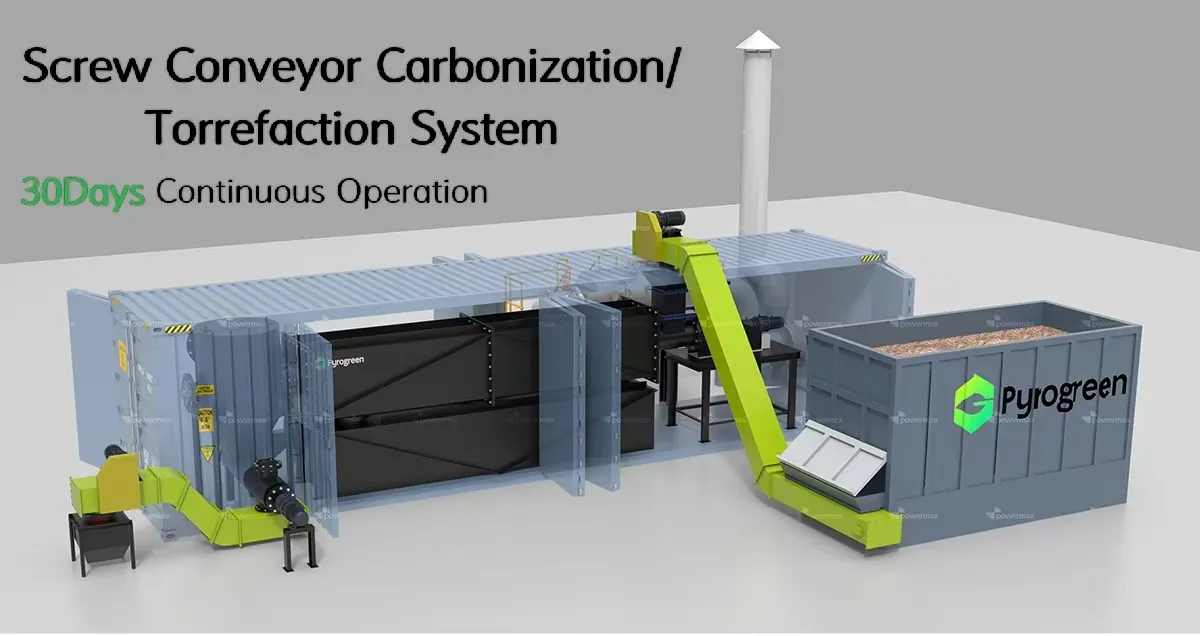

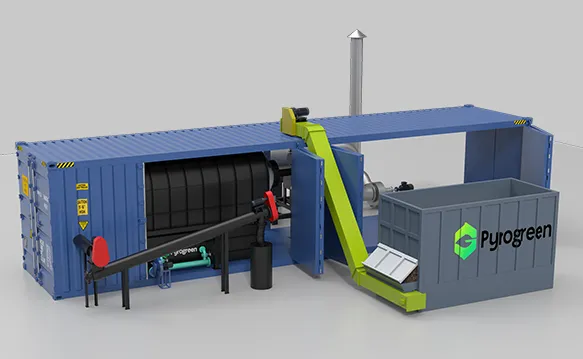

Screw Conveyor Carbonization/Torrefaction System

Nov 19, 2025

Screw Conveyor Carbonization/Torrefaction System

Continuous Pyrolysis Plant

❎Disadvantages of discontinuous pyrolysis equipment

|

✅Advantages of Screw Conveyor Carbonization/ Torrefaction System

|

|

Equipment congestion and frequent interruptions make it difficult to achieve large-scale profits. High energy consumption and low thermal energy utilization lead to high operating costs. It is difficult to meet emission standards and faces compliance difficulties and the risk of fines. The work intensity is high and requires frequent manual intervention, resulting in high labor costs. The unstable quality of oil and carbon black affects sales prices. |

Continuous and smooth operation to achieve scale and automation High thermal efficiency and significant reduction in operating costs Good sealing performance, easy centralized disposal of pollutants, and strong environmental compliance Highly automated, low labor demand The product quality is uniform and stable, with high added value |

Three Major Technological Breakthroughs in Screw Conveyor Carbonization/Torrefaction System for Modern Continuous Pyrolysis Plants

No Tar Continuous Pyrolysis Process |

Multi-stage Thermal Energy Recycling in Pyrolysis Technology |

Intelligent Dynamic Temperature Control in Modular Pyrolysis System |

|

The system adopts a special structural design to effectively alleviate the adhesion and slagging problems caused by high temperatures during the biomass pyrolysis process, ensuring long-term stable operation of the screw pyrolysis reactor and enabling efficient pyrolysis charcoal production. |

By integrating staged recovery of high-temperature flue gas with thermal energy reuse, the pyrolysis process significantly reduces additional fuel consumption required for system operation, while lowering exhaust emissions. This approach enhances the overall energy efficiency of the biomass waste pyrolysis machine. |

The automated pyrolysis unit can adjust the pyrolysis reactor for biochar in real time to achieve a stable and efficient pyrolysis environment. While improving the output quality of pyrolysis biochar, the system greatly reduces manual intervention and operational complexity. It is suitable for various applications such as coconut shell pyrolysis and rice husk pyrolysis, and can be implemented in systems including rotary kiln pyrolysis. |

Converting Biomass Waste into Value: A Continuous Pyrolysis Plant for Screw Conveyor Carbonization/Torrefaction

With its efficient pyrolysis process and stable operating performance, this continuous pyrolysis plant is ideal for industrial-scale biomass recovery and resource utilization. The following are specific processable raw materials and products from pyrolysis charcoal production:

|

|

Biomass Raw Materials for Pyrolysis

Acceptable material types: corn stalks, cotton stalks, sorghum stalks, charcoal forests, roots, branches, wood processing residues, rice husks, peanut shells, corn cobs, bagasse, palm shells, urban furniture waste, coconut shells, bamboo processing waste Pyrolysis biochar products: pyrolysis biochar, condensable flue gas (recoverable as wood vinegar), syngas |

Biomass Feedstock for Torrefaction

Acceptable material types: wood processing residues (such as sawdust), rice husks, peanut shells Torrefaction products: torrefied biomass (solid fuels with higher energy density and hydrophobicity), syngas |

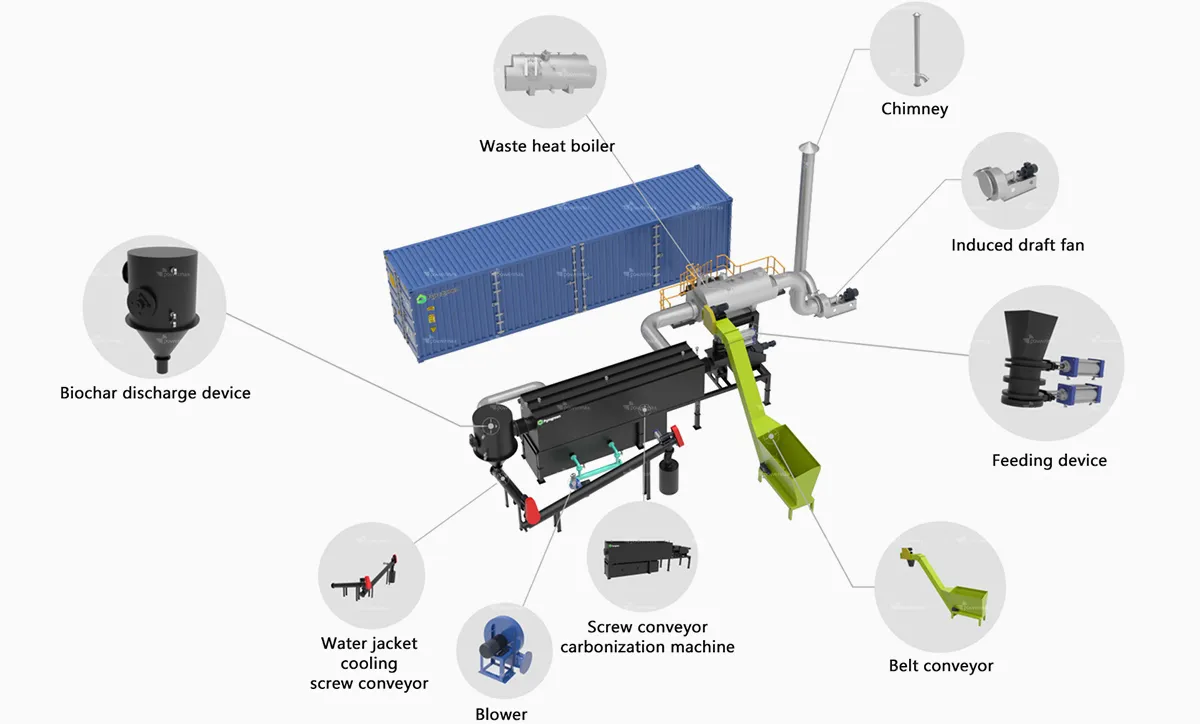

Working Principles and Advantages

The screw pyrolysis reactor adopts a sealed screw conveying design, in which materials are uniformly heated and undergo biomass pyrolysis during conveyance. By accurately controlling the temperature range, the pyrolysis reactor for biochar enables carbonization (medium to high temperature) or torrefaction (medium to low temperature). Its continuous feeding and discharging design ensures high processing efficiency and stable product quality, making it suitable for large-scale industrial continuous pyrolysis plant operation. The system supports various applications including coconut shell pyrolysis and rice husk pyrolysis.

Continuous Pyrolysis Plant: Converting Waste to Value via Carbonization

With its efficient heat transfer performance, precise pyrolysis process control and stable continuous pyrolysis plant operation capabilities, the screw pyrolysis reactor is an ideal biomass waste pyrolysis machine for large-scale biomass resource utilization. In an oxygen-free environment, this pyrolysis reactor for biochar thermochemically converts biomass through precise temperature control, producing high value-added pyrolysis biochar and various by-products. Specific treatable raw materials and corresponding products are as follows:

| Agricultural waste for pyrolysis |

Forestry residues for biomass pyrolysis |

Special fruit shells for no tar pyrolysis

|

Urban green waste processing

|

|

Acceptable raw material types: rice husks, wheat and corn stalks, corn cobs, peanut shells, sugarcane bagasse, cotton straw, sorghum straw, etc. Pyrolysis charcoal production outputs: pyrolysis biochar, wood vinegar, syngas |

Acceptable raw material types: fast-growing charcoal forests, roots, branches, wood processing scraps, bamboo processing waste, etc. Pyrolysis technology products: pyrolysis biochar, wood vinegar, syngas |

Acceptable raw material types: high-hardness fruit shells such as palm shells and coconut shells Coconut shell pyrolysis products: pyrolysis biochar, wood vinegar, syngas |

Acceptable raw material types: urban garden pruning waste, sorted waste wooden furniture, etc. Pyrolysis machine for biochar outputs: pyrolysis biochar, wood vinegar, syngas |

Diversified high-value applications

Screw Pyrolysis Reactor Parameters

| Model | BSCC1000 | BSCC5000 |

| Feed Rate | 1m³/(300kg) | 5m³/(500kg) |

| Footprint(L*H) | 16m*10.5m | 21m*11m |

| Working Mode | Continuous | |

| Feed Requirements | Size≤20mm(5-8mm is optimal),MC≤15% | |

| Control Mode | PLC Control System | |

| Material | SS310S+SS304 | |

| Pressure | Micro Negative Pressure | |

| Heating Fuel | Diesel,natural gas ,heavy oil,etc | |

| Heating Mode | Indirect Heating | |

| Noise(dB) | ≤80 | |

| Cooling Mode | Circulating Water Cooling | |

Technological Highlights of the Continuous Pyrolysis Plant: Screw Conveyor Carbonization/Torrefaction System

Efficient Pyrolysis Conversion

Precise pyrolysis process control: Adopts multi-stage independent temperature zone design to ensure uniform heating and transformation during biomass pyrolysis under the preset optimal temperature curve, significantly improving the yield and quality of pyrolysis biochar.

No tar pyrolysis environment: By integrating an inert gas protection system, a stable oxygen-free atmosphere is automatically maintained throughout the pyrolysis reactor for biochar, effectively eliminating biomass combustion and ensuring reaction purity and safety.

Intelligent Operation of Modular Pyrolysis System

Automated pyrolysis unit control: An intelligent system based on a programmable logic controller automatically adjusts and monitors key parameters such as feeding, temperature, and residence time, achieving stable operation of the continuous pyrolysis plant.

Modular pyrolysis system design: The biomass waste pyrolysis machine adopts a highly modular structure, facilitating rapid integration and transportation, significantly reducing installation complexity and infrastructure costs.

Clean Energy Efficiency Optimization

Syngas resource utilization: Utilizing a unique gas-phase treatment unit, volatiles generated from pyrolysis charcoal production are converted into combustible gas and reused for system self-heating, enabling clean production without tar or waste liquid emissions.

Efficient waste heat recovery: The screw pyrolysis reactor incorporates a built-in waste heat recovery device that utilizes heat energy from high-temperature products to pre-treat feedstock, effectively improving overall thermal efficiency in biomass pyrolysis.

Our Excellence Projects

Real-world implementations of our continuous pyrolysis technology, delivering sustainable solutions and carbon credit opportunities worldwide.

|

Carbon Asset Development Project #1Malaysia 2MW Biomass (EFB) Gasification Heating Project

Biomass Heating Solution

|

Project Overview

The Malaysia Biomass Gasification Heating Project involves the installation of one set of Powermax® TFBG equipment from PyroGreen. The syngas produced is used to replace diesel in diesel boilers for heating, with high-quality biochar as a byproduct for agricultural applications. Project DataLocationMalaysia Project Period2024 - Present Biomass FeedstockEFB Briquettes Daily consumption: ~57.6 tons

Annual Biochar Production~1,920 tons CO₂ Sequestration2,970.88 tons Calculated: 1,920t × 44/12 × 42.2%

Estimated Annual Carbon Credits~1,500 tons |

|

Carbon Asset Development Project #2Malaysia 3MW Biomass Gasification Power Generation Project

Power Generation Solution

|

Project Overview

The Malaysia 3MW Biomass Gasification Power Generation Project involves the installation of two sets of Powermax® TFBG equipment from PyroGreen. The syngas produced is used for electricity generation, with high-quality biochar as a byproduct for agricultural applications. Project DataLocationMalaysia Project Period2025 - Present Biomass FeedstockWood Chips Daily consumption: ~77.6 tons

Annual Biochar Production~2,586 tons CO₂ Sequestration7,301.14 tons Calculated: 2,586t × 44/12 × 77%

Estimated Annual Carbon Credits~3,600 tons |

|

Carbon Asset Development Project #3Myanmar 12MW Biomass Gasification Power Station

Large-scale Power Generation

|

Project Overview

The Myanmar Biomass Gasification Power Station Project involves the installation of twelve sets of Powermax® DFBG equipment from PyroGreen. The syngas produced is used for electricity generation, with high-quality biochar as a byproduct for fishery feed and agricultural applications.

Project DataLocationMyanmar Project Period2023 - Present Biomass FeedstockRice Husk Daily consumption: ~518.4 tons

Annual Biochar Production~51,840 tons CO₂ Sequestration93,139.2 tons Calculated: 51,840t × 44/12 × 49%

Estimated Annual Carbon Credits~45,000 tons |

|

Carbon Asset Development Project #4Indonesia 1MW Biomass Gasification Power Station

Compact Power Solution

|

Project Overview

The Indonesia Biomass Gasification Power Station Project involves the installation of two sets of Biowatt™ 500 equipment from PyroGreen. The syngas produced is used for electricity generation, with high-quality biochar as a byproduct for agricultural applications. Project DataLocationIndonesia Project PeriodNov 2024 - Present Biomass FeedstockCoconut Shell or Wood Chips Daily consumption: ~28.8 tons

Annual Biochar Production~768 tons CO₂ Sequestration1,484 - 2,168 tons Calculated: 768t × 44/12 × (52.7% - 77%)

Estimated Annual Carbon Credits500 - 1,000 tons |

Workflow of Continuous Pyrolysis Machine: Screw Conveyor Carbonization/Torrefaction System

As a leader in advanced pyrolysis technology, PyroGreen provides customized screw pyrolysis reactor solutions for pyrolysis charcoal production from various biomass feedstocks. This process, sometimes referred to as torrefaction, converts biomass into high-quality pyrolysis biochar through specialized pyrolysis process expertise. Our continuous pyrolysis plant can be designed as a modular pyrolysis system or automated pyrolysis unit tailored to your specific biomass waste pyrolysis machine requirements, including specialized applications for coconut shell pyrolysis and rice husk pyrolysis. PyroGreen's technical team will design the optimal pyrolysis reactor for biochar based on your unique feedstock characteristics.

Keep up with policy trends: Give priority to continuous pyrolysis equipment

As global environmental regulations tighten, governments are pushing the industry in a greener, more efficient and more sustainable direction. Continuous pyrolysis equipment is a wise choice, especially when considering the following policy trends:

The government's ban on intermittent

Government ban: Many countries are phasing out traditional intermittent systems due to pollution and safety risks. For example, in 2023, the State Council of China has ordered the complete elimination of non-compliant fixed-bed batch gasifiers. Continuous systems use closed-loop operation and fully automated control, making them cleaner, safer, and more likely to meet future regulatory standards.

Continuous policy incentives

Policy incentives: The government provides subsidies, tax incentives and green financing for advanced low-emission equipment. Continuous pyrolysis machines qualify for such support because of their high energy efficiency and better emission control, helping investors reduce costs and attract ESG investment.

Easier to pass the EIA

Easier access to environmental approvals: Environmental impact assessments and safety assessments are easier to pass with a continuous system. Its steady-state operation and reliable emission control simplify the compliance process, speed up permit approvals, and reduce project delays.

Contribution of Screw Pyrolysis Technology to the Industry

With the global pursuit of "dual carbon" goals and circular economy, various industries are actively seeking green transformation paths. Screw pyrolysis reactor technology, as an efficient biomass pyrolysis solution, is becoming a core support for sustainable development in the following key sectors:

Agriculture and Forestry

This industry generates substantial waste including straw, rice husks, and wood chips. Using a biomass waste pyrolysis machine, you can achieve: High-value waste conversion: Transform low-density, perishable biomass into high-energy-density pyrolysis biochar or biocoal, turning waste into wealth while eliminating pollution from open burning. Production of soil amendments: The high-quality pyrolysis biochar produced can restore acidic and compacted soil, enhance fertility, sequester carbon, and support ecological agriculture. |

Energy Industry

Facing pressure to adjust energy structure and reduce carbon, this sector benefits significantly from pyrolysis technology: Supply of green fuel: The pyrolysis process converts biomass into biocoal with energy density close to coal, serving as a direct alternative or blended fuel for power plants to reduce carbon emissions economically. Enhance industry green image: Large-scale application of biomass pyrolysis technology demonstrates commitment to ESG responsibilities and helps gain policy support and market recognition. |

High-grade Industrial Materials Manufacturing

Metallurgical, chemical, and activated carbon industries require stable, high-carbon materials. The screw pyrolysis reactor offers: High-quality raw material substitution: The pyrolysis biochar produced features high fixed carbon and stable properties, ideal for manufacturing carbon-based fertilizers, activated carbon, and metallurgical reductants, reducing reliance on fossil-based feedstocks. Green supply chain achievement: Using biomass waste to produce industrial materials builds a carbon-negative industrial chain—"biowaste to green materials to advanced manufacturing"—significantly boosting product environmental value and competitivenes |

If you are interested in investing in screw pyrolysis reactors, please follow the following steps to promote cooperation:

1. Technical consultation: Contact us through official channels to briefly explain your project needs and goals.

2. Submit project parameters: Provide key information such as specific raw material characteristics, expected processing capacity, site conditions and product use.

3. Get customized solutions: We will provide you with exclusive process design, equipment configuration and detailed quotations based on your needs.

4. On-site inspection verification: Welcome to visit and inspect the operating status of the equipment and conduct raw material testing.

5. Signing and implementation: After both parties confirm the plan and sign the contract, we will arrange production, equipment installation and system debugging.

The spiral pyrolysis reactor provides you with a mature and reliable continuous pyrolysis solution that can efficiently convert various organic waste into high value-added energy and chemical products. This technology can not only create significant economic returns, but also play an important role in realizing waste resources and reducing carbon emissions, effectively promoting the development of circular economy.

Whether you need to deal with agricultural residues, industrial organic waste residue, or municipal sludge, based on spiral pyrolysis technology, we can provide you with highly matched personalized system solutions.

Please contact us today to start your efficient and environmentally friendly resource recycling project and turn waste materials into sustainable economic benefits!