Pyrolysis Machine for Biochar: Unlocking Value from Biomass Waste

Nov 24, 2025

Pyrolysis Machine for Biochar: Unlocking Value from Biomass Waste

The Core of Production: The Pyrolysis Reactor for Biochar

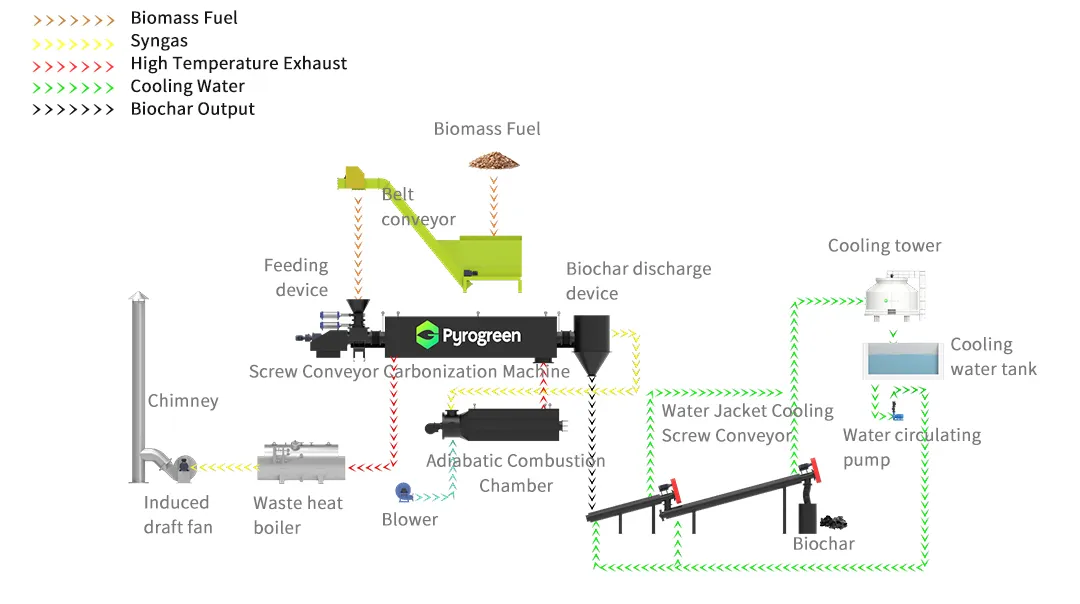

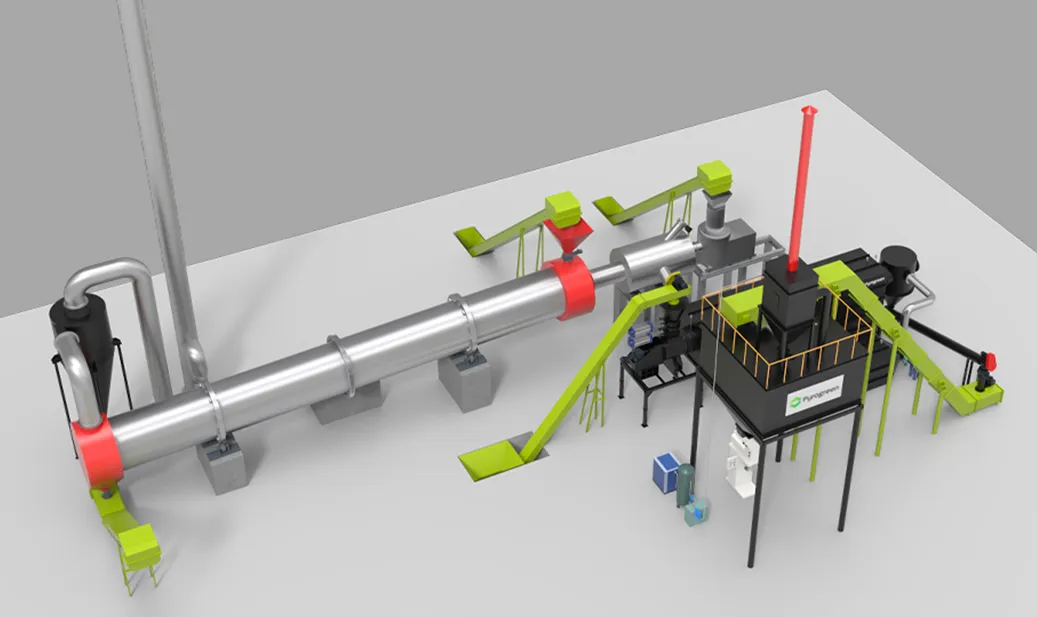

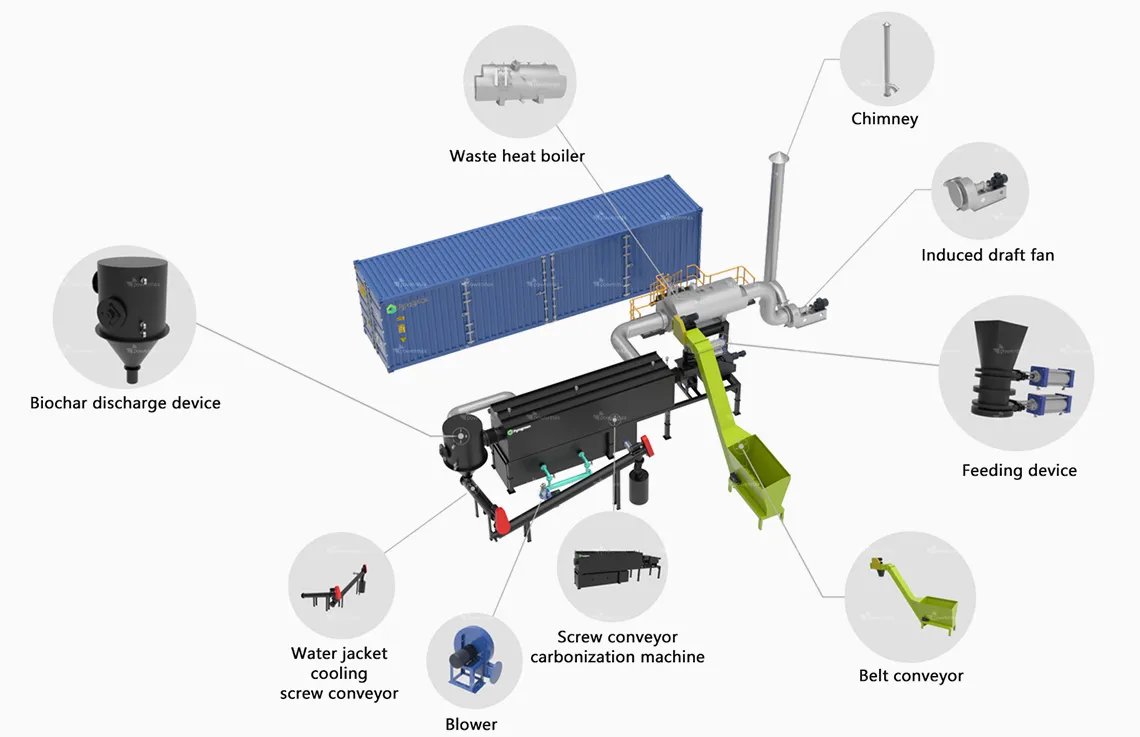

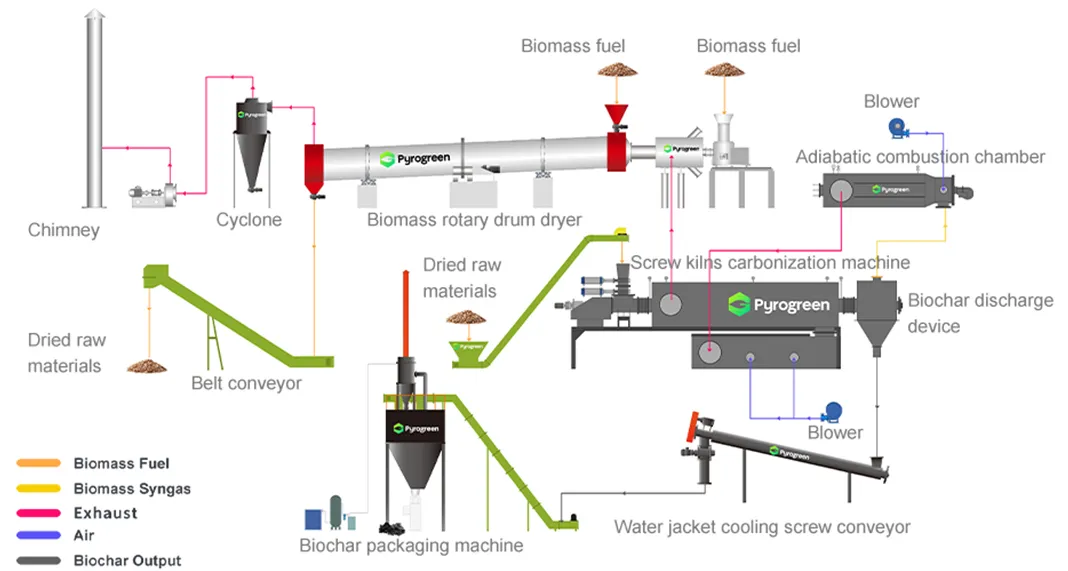

At the heart of the conversion process lies the pyrolysis reactor for biochar. Using a screw conveyor system for carbonization represents one of the most straightforward, quantifiable, and cost-effective carbon capture and storage technology paths available today. The biomass pyrolysis process occurs at high temperatures, typically between 350°C and 900°C, releasing significant heat. An efficient pyrolysis reactor for biochar is designed not only to facilitate this transformation but also to capture and reuse the excess energy, which would otherwise be lost to the environment. This approach to pyrolysis biochar production turns waste heat into a valuable asset, stabilizing long-term operating costs by reducing reliance on grid electricity.

Generating Power from Process Heat

The Pyrogreen carbonization system uses advanced thermochemical conversion technology and combines a patented high-temperature resistant screw transport reactor to convert various biomass into high value-added green biochar. As the core equipment of carbonization, the modular pyrolysis system is specially designed for distributed processing scenarios. It has both carbon removal and energy recovery functions. In addition to carbon sequestration, it can also produce renewable synthetic gas.

Enhancing Value with Biochar Carbon Credits

The production of pyrolysis biochar is a recognized industrial carbon sequestration solution. Organic raw materials like wood, manure, and straw are rich in carbon, making them ideal for carbon capture. The permanence of carbon stored in biochar gives it a significant advantage in carbon credit markets. To obtain these credits, projects must utilize sustainable biomass, operate standardized pyrolysis equipment, and complete registration with a carbon credit agency. The market outlook is strong, with demand for biochar carbon credits projected to grow substantially in the coming decade.

|

Planershavings |

Woodpelletsfines Woodpelletsfines |

Bark Bark |

Teawaste Teawaste |

|

|

EmptyFruitBunch |

Cottonstalk Cottonstalk |

Corncob Corncob |

Woodchips Woodchips |

Cornstraw Cornstraw |

Ricehusk Ricehusk |

Coconutshell Coconutshell |

Charcoalforest Charcoalforest |

Bambooslices Bambooslices |

Bambooprocessingwaste Bambooprocessingwaste |

Bagasse Bagasse |

System Compatibility and Industrial Scale

Each automated pyrolysis unit from Pyrogreen is engineered for high-temperature operation, often exceeding 700°C, creating ideal conditions for waste heat recovery. Our modular pyrolysis system can process diverse feedstocks, from agricultural and forestry residues to livestock manure. According to market research, the global biochar market is expected to grow significantly, supported by renewable energy policies that recognize biochar as a viable carbon capture pathway.

Introducing the PyroGreen Continuous Pyrolysis Machine

PyroGreen Technology specializes in transforming biomass into high-value green carbon products through advanced thermochemical processes. Our solutions are centered on a sophisticated continuous pyrolysis machine that ensures efficiency and reliability.

Process Overview

As a leader in thermochemical processing, PyroGreen provides customized screw-conveyor carbonization systems. This biomass pyrolysis process, sometimes termed roasting, converts biomass into high-quality biochar and requires deep expertise. Our specialists design the optimal modular pyrolysis system based on your specific raw material characteristics.

System Advantages

Modular Design: Our modular pyrolysis system allows for easy transportation, swift installation, and scalability.

High Thermal Efficiency: The design of our pyrolysis reactor for biochar ensures superior heat transfer, guaranteeing high biochar yield and quality.

Clean Operation: The process generates no tar or liquid waste, making it an environmentally sound automated pyrolysis unit.

Full Automation: The continuous pyrolysis machine operates with minimal manual intervention, ensuring consistent output and safety.

Low Emissions: The system maintains extremely low emissions of nitrogen oxides, carbon monoxide, and particulate matter.

By integrating an automated pyrolysis unit like PyroGreen's continuous pyrolysis machine, producers can achieve a sustainable, profitable, and scalable operation for producing high-quality biochar.

Featured Projects

Discover our global biochar and carbon credit projects that demonstrate the practical application and financial benefits of pyrolysis technology.

|

|

Carbon Asset Development Project – Malaysia 2MW Biomass (EFB) Gasification Heating ProjectProject OverviewThe Malaysia Biomass Gasification Heating Project involves the installation of one set of Powermax®TFBG equipment. The produced syngas replaces diesel in diesel boilers for heating, with high-quality biochar as a by-product for agricultural applications. Project Data

|

Carbon Asset Development Project – Malaysia 3MW Biomass Gasification Power ProjectProject OverviewThis 3MW biomass gasification power project in Malaysia utilizes two sets of Powermax®TFBG equipment to generate electricity from syngas. The process yields high-quality biochar as a by-product for agricultural use. Project Data

|

|

|

Carbon Asset Development Project – Myanmar 12MW Biomass Gasification Power StationProject OverviewThe Myanmar Biomass Gasification Power Station project features twelve sets of Powermax®DFBG equipment generating electricity from syngas. The high-quality biochar by-product is utilized in fisheries feed and agricultural applications. Project Data

|

Carbon Asset Development Project – Indonesia 1MW Biomass Gasification Power StationProject OverviewThis Indonesian project employs two sets of Biowatt™500 equipment to generate electricity from syngas. The resulting high-quality biochar is applied in agricultural sectors, supporting sustainable farming practices. Project Data

|

Whether you need to deal with agricultural residues,industrial organic waste residue, or municipal sludge, based on spiral pyrolysis technology, we can provide you with highly matched personalized system solutions.

Please contact us today to start your efficient and environmentally friendly resource recycling project and turn waste materials into sustainable economic benefits!

Contact our engineering team for a complimentary feasibility assessment. We'll analyze your specific biomass streams and provide a detailed economic model showing potential returns,environmental impact, and implementation roadmap.

Grainstraw

Grainstraw