The Biomass Carbonization System: A Complete Guide to Converting Waste into Value

Nov 07, 2025

The Biomass Carbonization System: A Complete Guide to Converting Waste into Value

For global industries managing organic waste, the modern Biomass Carbonization System represents a pivotal shift from disposal cost to circular profit. This technology transforms agricultural, forestry, and municipal biomass into high-value biochar and clean energy. This guide explores how a sophisticated Biomass Carbonization System, like the Pyrogreen series, operates and creates tangible returns on investment.

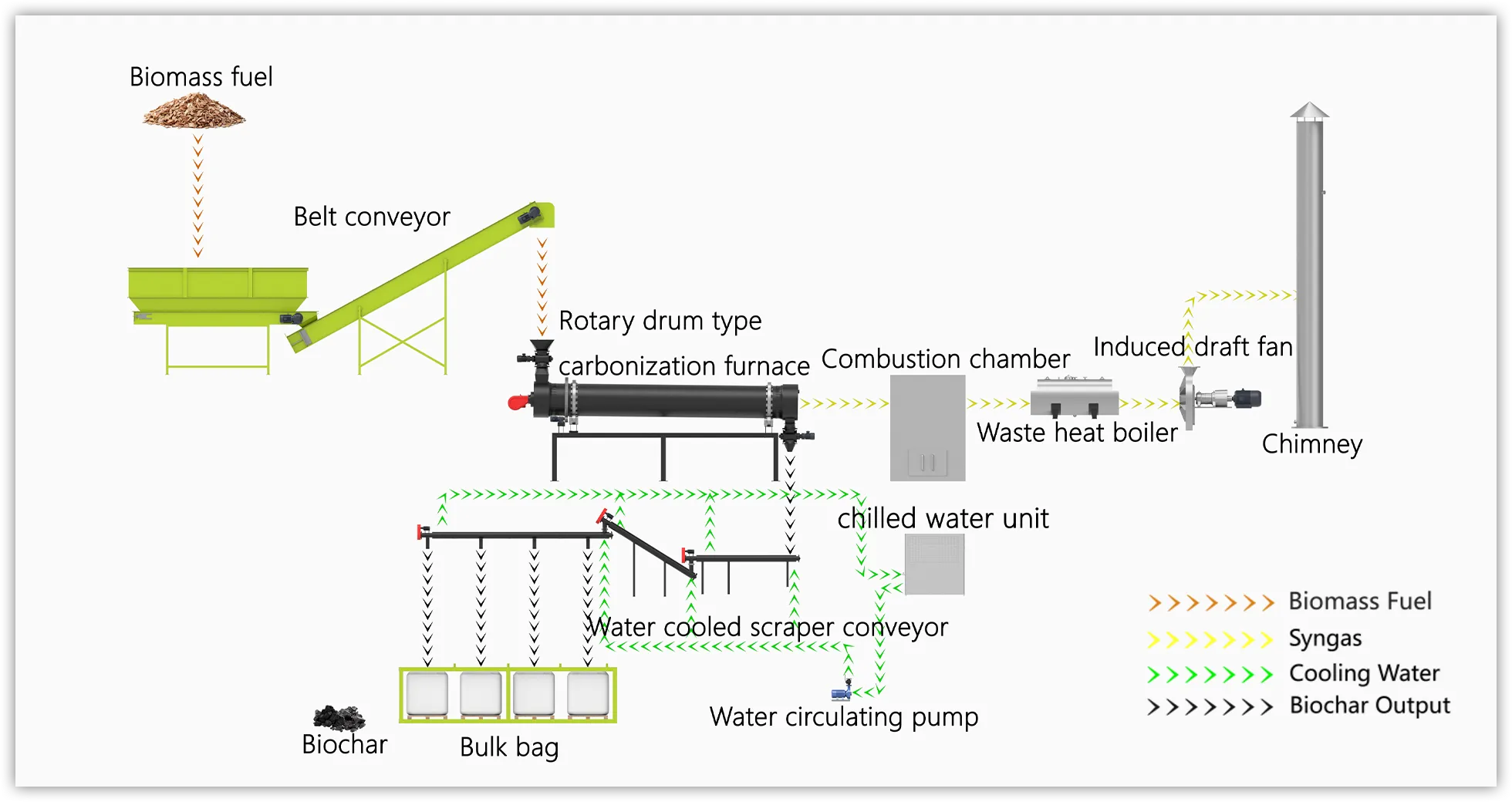

How Our Biomass Carbonization System Works

A fully integrated Biomass Carbonization System is engineered for continuous, automated operation. The process is a model of industrial efficiency, designed to handle feedstock from intake to final product with minimal operator intervention.

| Precise Feeding | The process begins with a belt conveyor that uniformly delivers raw biomass into the system. |

| The Core Conversion | The material enters the heart of the Biomass Carbonization System: the screw conveyor carbonization machine. This reactor applies intense heat in an oxygen-limited environment, initiating the pyrolysis process that converts solid biomass into biochar and syngas. |

| Energy Self-Sufficiency | The syngas is not wasted. It is redirected to fuel the system's own combustion chamber, creating a closed-loop energy cycle that drastically reduces or eliminates the need for external fuel. |

| Maximum Heat Recovery | Beyond self-powering, the system captures excess thermal energy through a waste heat boiler, generating steam for external applications and maximizing overall energy efficiency. |

| Safe Product Handling | The newly produced, high-temperature biochar is discharged into a water-cooled scraper conveyor. This critical step rapidly cools the material, preserving its quality and preventing spontaneous combustion. The finished biochar is then ready for bulk bag packaging. |

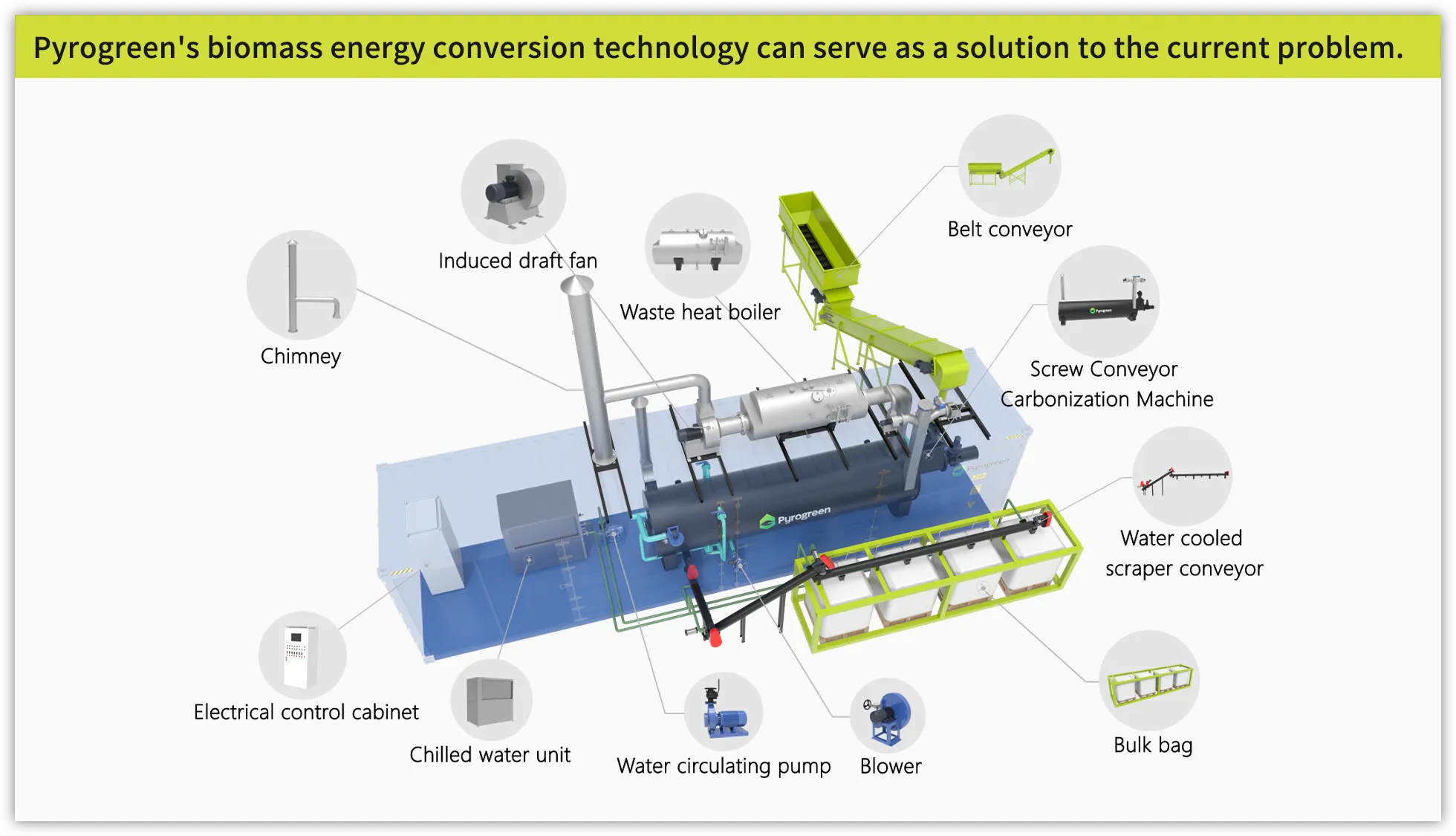

Key Components of a High-Efficiency Biomass Carbonization System

The reliability of any Biomass Carbonization System depends on its core components. The Pyrogreen series is built with durability and performance as the top priorities.

| The Carbonization Furnace | Constructed from 310S stainless steel to withstand prolonged high-temperature operation without degradation. |

| Automated Control Cabinet | Allows for precise management of temperature, feed rate, and pressure, ensuring consistent output and easy operation. |

| Integrated Cooling Conveyor |

Essential for stabilizing the biochar and making it safe for storage and transport. |

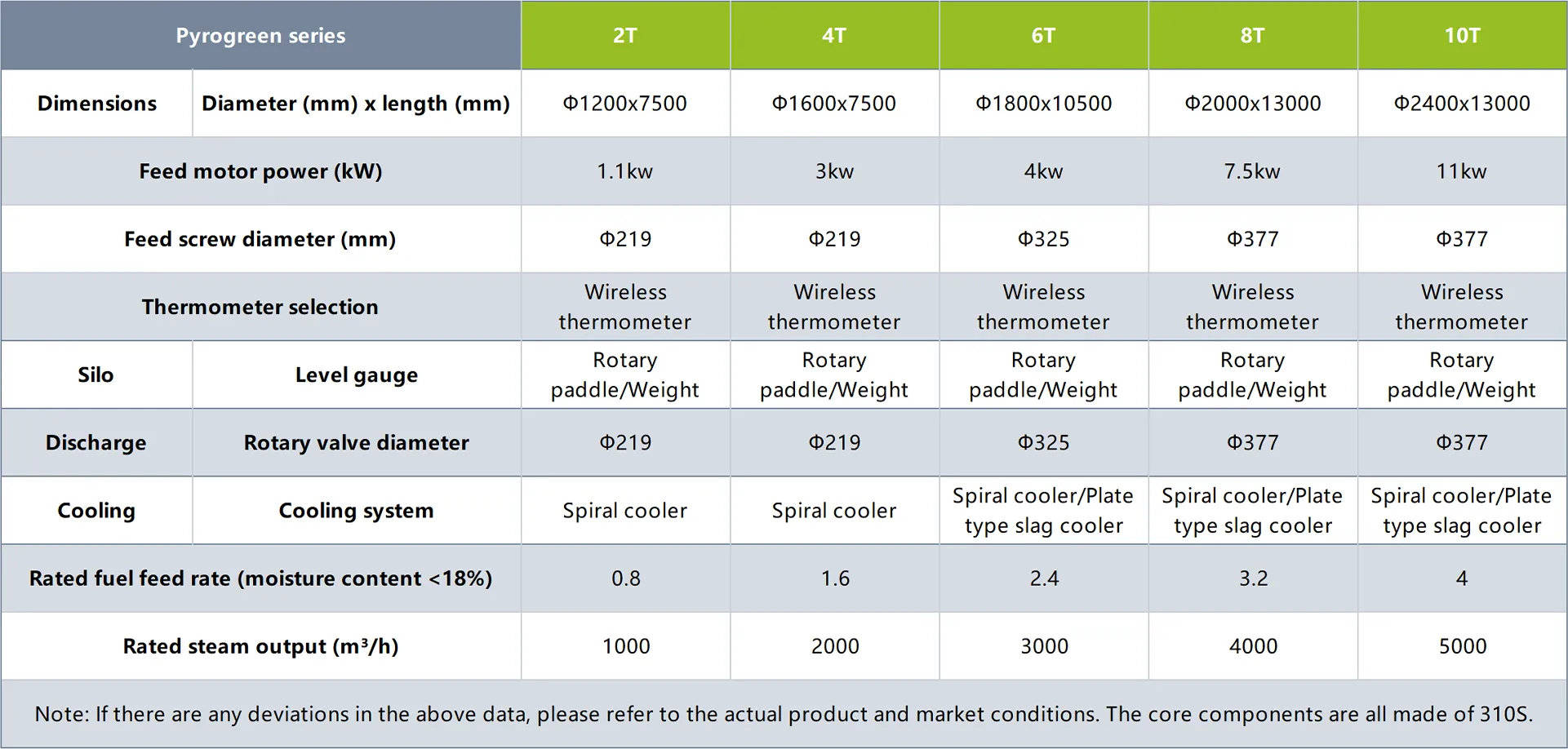

Selecting the Right Model: Specifications of Our Biomass Carbonization System

Choosing the correct capacity is crucial. The Pyrogreen Biomass Carbonization System is available in multiple models to match specific operational throughput goals, from pilot-scale projects to large industrial processing.

Note: All models feature 310S stainless steel core components for maximum durability.

The Strategic Advantages of Implementing a Biomass Carbonization System

Investing in a Pyrogreen Biomass Carbonization System delivers a compelling competitive edge by addressing both economic and environmental objectives.

| Create New Revenue Streams | Convert waste liabilities into sellable products like biochar for agriculture and renewable steam for industrial use. |

| Drastically Reduce Disposal Costs | Eliminate expenses associated with waste hauling, landfilling, or open burning. |

| Achieve Energy Independence |

Generate internal process heat, shielding your operations from external energy price volatility. |

| Meet and Exceed Sustainability Goals |

This system provides a verifiable path to carbon neutrality and beyond, supporting global circular economy initiatives. |

Conclusion: The Pyrogreen Biomass Carbonization System as Your Strategic Partner

The Pyrogreen Biomass Carbonization System is more than just a piece of machinery; it is a strategic asset for any organization serious about resource efficiency and sustainable growth. By adopting this technology, you are not just managing waste—you are activating a new, profitable, and eco-positive operational model.

Ready to calculate the ROI a Pyrogreen Biomass Carbonization System can bring to your operation? Contact our engineering team for a personalized feasibility analysis and system recommendation.