Transforming Biomass: How Advanced Torrefaction Technology Creates Carbon-Negative Solutions

Nov 05, 2025

Transforming Biomass: How Advanced Torrefaction Technology Creates Carbon-Negative Solutions

What is Biomass Torrefaction Technology?

Biomass torrefaction technology involves an advanced thermal process that transforms raw biomass into energy-dense, stable carbon products through controlled heating in oxygen-limited environments. This sophisticated biomass torrefaction process represents a significant improvement over traditional methods, creating uniform, hydrophobic materials with enhanced fuel properties.

Why Torrefaction Technology Matters: The Business Case

Carbon Negative Solution

Every ton of torrefied biomass produced using modern biomass torrefaction technology permanently removes approximately 2.5-3 tons of CO₂ from the atmospheric cycle while displacing fossil fuels in energy applications.

Economic Advantages of Torrefaction Systems

Converts waste liabilities into multiple revenue streams

Creates premium-priced biochar products for various markets

Generates verifiable carbon credits for emissions trading

Significantly reduces waste disposal and handling costs

Provides energy self-sufficiency through process optimization

Pyrogreen's Advanced Torrefaction Equipment Solutions

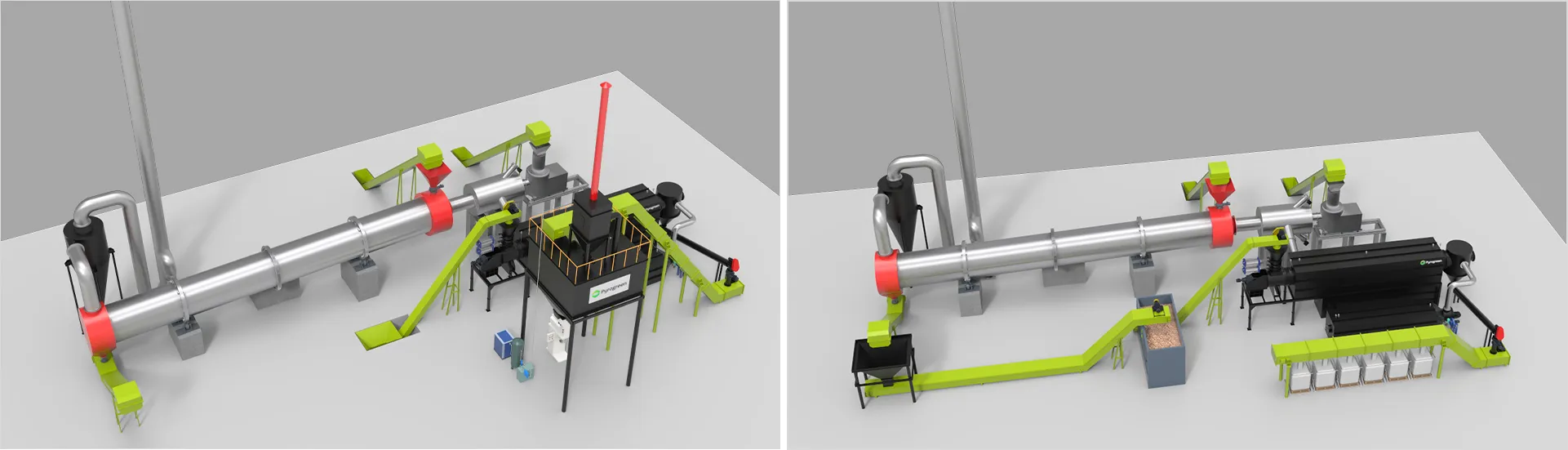

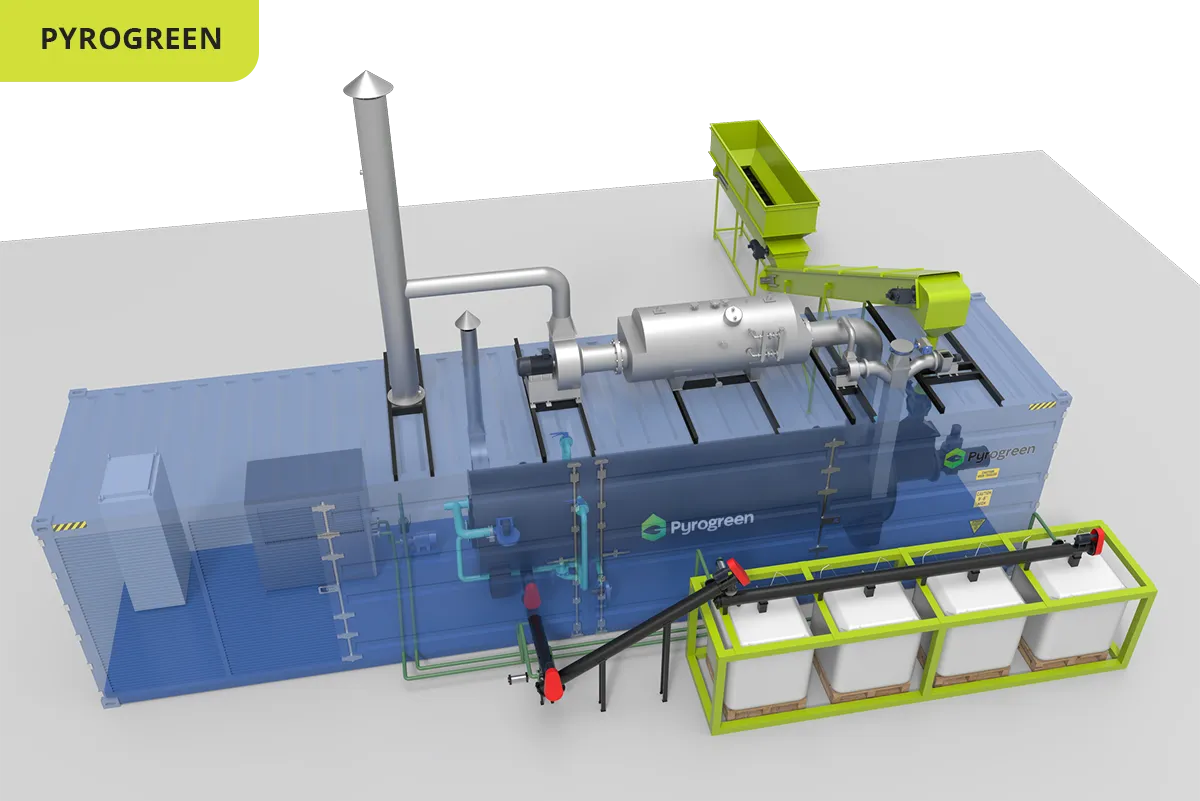

Screw Conveyor Torrefaction System

Our flagship screw conveyor torrefaction machine represents the pinnacle of biomass torrefaction technology, featuring:

Continuous-Feed Design

Fully enclosed reactor system ensures consistent processing Precise temperature control (200-300°C) under oxygen-free conditions Uniform heat distribution for premium product quality Modular torrefaction plant configuration for scalable deployment |

Zero-Waste Operation

No tar or liquid waste production Complete utilization of process gases for energy recovery Extremely low NOx, CO, and particulate emissions Clean, environmentally compliant operation |

Key Performance Metrics of Our Torrefaction Technology

Process Efficiency

40% reduction in energy consumption versus conventional carbonization 85% mass yield retention with significantly enhanced energy density Continuous operation with minimal downtime requirements Automated controls reduce labor costs and improve consistency |

Economic Performance

Typical ROI period of 18-36 months Multiple revenue streams from products and credits Reduced operational costs through energy optimization Scalable investment with modular torrefaction equipment |

Applications & Market Opportunities

Energy Sector Integration

Direct coal replacement in existing power infrastructure Industrial heating applications for manufacturing Renewable fuel production for transportation Distributed energy generation systems |

Carbon Management Solutions

Soil amendment for agricultural enhancement Carbon sequestration projects for emissions offset Industrial materials enhancement applications Verified carbon credit generation programs |

Implementation Timeline

Phase 1: Technical Assessment (2-3 weeks)

Comprehensive feedstock analysis and characterization Site evaluation and infrastructure assessment Detailed economic modeling and ROI projection |

Phase 2: System Installation (4-6 weeks)

Modular torrefaction equipment delivery and setup System commissioning and performance verification Operator training and documentation handover |

Phase 3: Ongoing Operation

Continuous production with remote monitoring Performance optimization and technical support Revenue generation from product streams |

Case Study: Rice Husk Valorization

Input Materials

1 ton of rice husks (agricultural waste) |

Output Products

500 kg of premium quality biochar Carbon credits for 2.5 tons CO₂ equivalent Process energy for adjacent operations |

Revenue Generation

Biochar sales: $250-400 Carbon credits: $150-300 Waste processing fees: $50-100 Energy cost savings: $30-60 |

Why Choose Pyrogreen Torrefaction Technology?

Proven Technology Platform

Multiple successful installations worldwide Robust engineering with continuous improvement Verified performance data and case studies |

Economic Certainty

Predictable operational costs and performance Multiple diversified revenue streams Rapid return on investment with clear metrics |

Environmental Leadership

Verifiable carbon removal and sequestration Zero waste operation with full compliance Sustainable resource utilization practices |

Next Steps: Request Your Feasibility Assessment

Contact our engineering team for a complimentary feasibility assessment. We'll analyze your specific biomass streams and provide a detailed economic model showing potential returns, environmental impact, and implementation roadmap.

Take Action Today

Position your organization at the forefront of carbon-negative technology while creating new revenue streams from existing waste materials. The carbon economy is here - leverage advanced biomass torrefaction technology to transform your operations and environmental impact.