.webp)

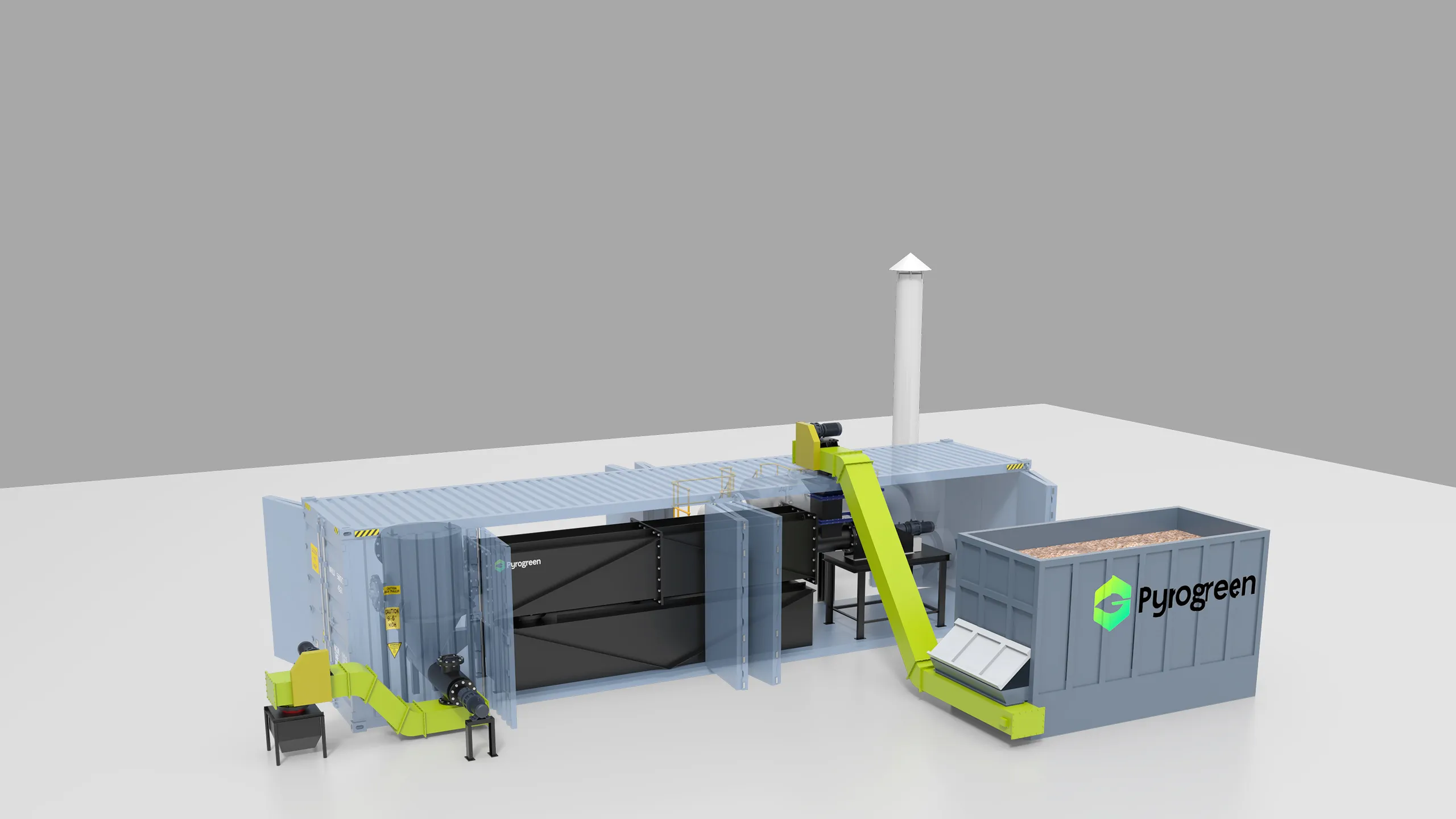

Our biomass carbon removal (BCR) plant converts agricultural and forestry residues into high-value biochar, allowing companies to generate carbon credits and support carbon reduction, environmental protection, and sustainable development.

How to Generate Carbon Credits with Biochar

Pyrogreen's carbonization systems convert diverse biomass into high-quality biochar. This process sequesters carbon and generates carbon credits certified by Verra and Puro.earth.

BCR: Biochar Carbon Removal Technology

Biomass Carbon Removal (BCR) thermochemically converts residues into stable biochar, achieving long-term carbon sequestration and generating carbon credits through biochar.

Pyrolysis: Generating Carbon Credits with Biochar

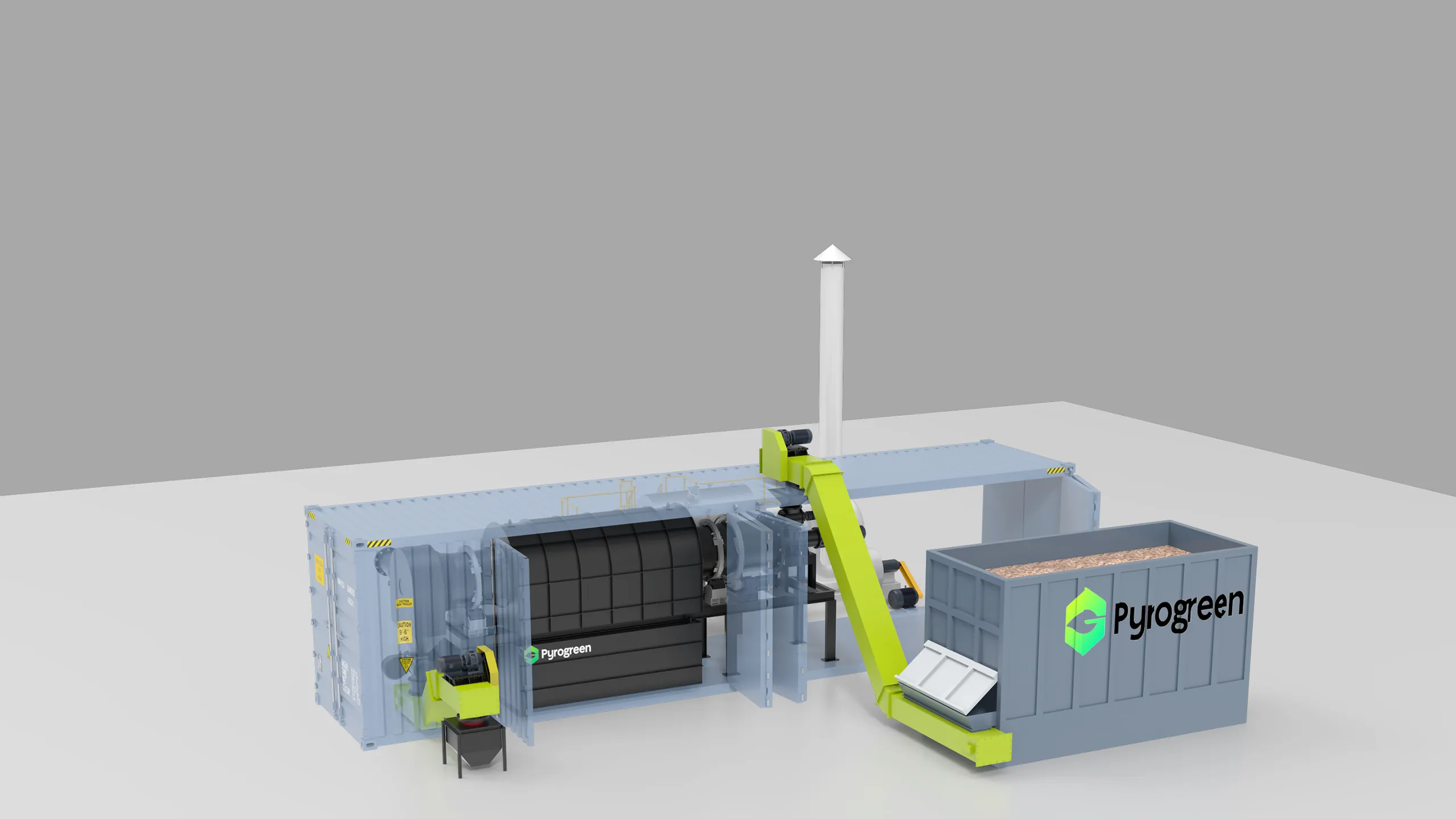

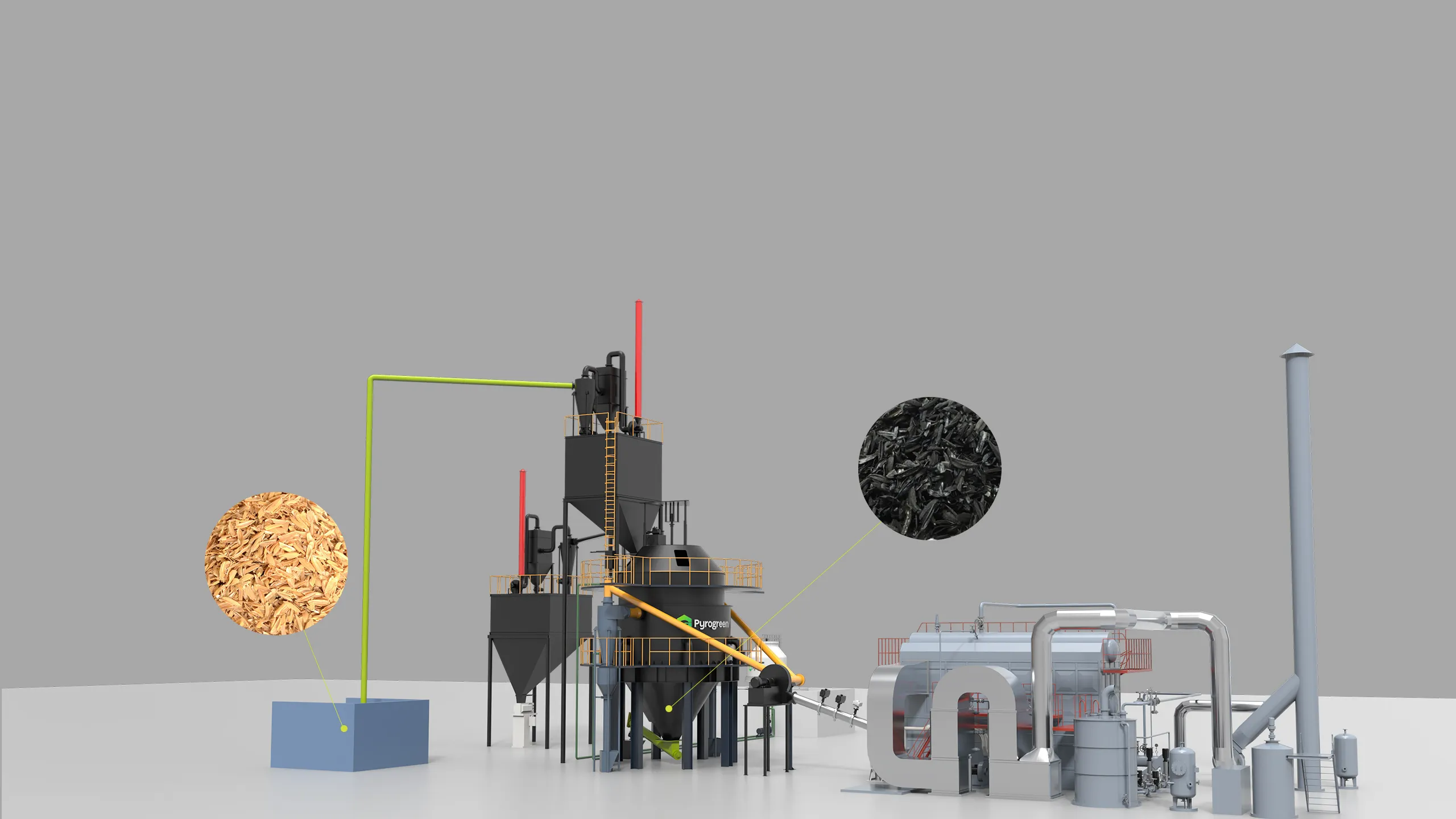

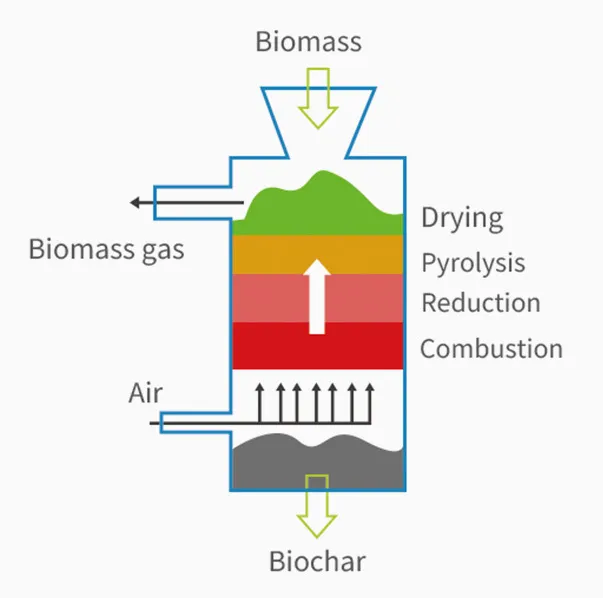

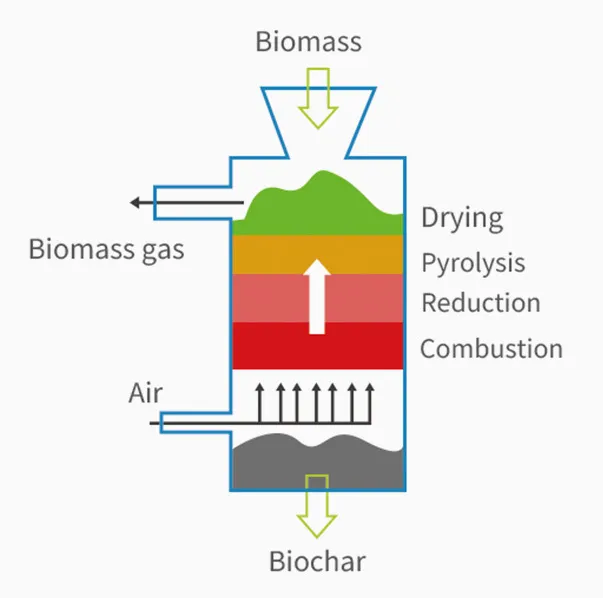

Taking the pyrogreen biomass updraft fixed-bed carbonizer as an example.

This equipment converts biomass such as wood chips, bamboo chips, coconut shells, and fruit shells into biochar and combustible gas in a low-oxygen environment. The biomass is then piped to the heating system as fuel gas.

Biomass Carbon Removal (BCR) thermochemically converts residues into stable biochar, achieving long-term carbon sequestration and generating carbon credits through biochar.

| Feeding |

Biomass feedstock is conveyed via belt conveyor into the updraft fixed-bed carbonizer for oxygen-limited pyrolysis, producing biochar and syngas. |

|

| Gas Treatment |

The pyrolysis gases pass through a cyclone dust collector for particulate removal

|

|

Combustible components are fully oxidized in the decomposition furnace

|

|

An induced draft fan maintains airflow before emission through the stack

|

| Product Cooling |

The produced biochar is cooled by a cooling tower and a water-cooled screw conveyor, and the system temperature is maintained by circulating cooling water in a cooling water pool. |

The biochar is applied to soil as an amendment, enabling long-term carbon storage.

Value of Pyrolysis

Carbon Sequestration

According to the 2019 Refinement to the 2006 IPCC Guidelines for National Greenhouse Gas Inventories by the Intergovernmental Panel on Climate Change (IPCC), biochar application is recognized as a significant carbon removal method. Its carbon sequestration timeframe can span centuries to millennia. The International Biochar Initiative (IBI) states that approximately 50% of biomass carbon can be stabilized in biochar for long-term storage through pyrolysis.

|

Soil Amendment

Mechanism: Biochar’s porous structure enhances soil aggregation, increases cation exchange capacity (CEC), improves water and nutrient retention, and neutralizes acidic soils.

|

Empirical Support

Meta-analyses (e.g., studies published in GCB Bioenergy) show that biochar application increases crop yields by 10–20% on average, with particularly significant effects in degraded soils.

|

Energy Substitution:

Syngas and bio-oil produced during pyrolysis can be used as renewable energy for process heating or electricity generation, replacing fossil fuels and enabling a carbon-negative cycle.

|

International Carbon Credits

The technology is recognized by international carbon credit standards (e.g., Verra’s VCS, Puro.earth), allowing the generation of tradable carbon credits to incentivize commercialization.

|

Efficient Biomass Pyrolysis System Pyrogreen Technological Advantages

With multiple core patents and over 20 years of manufacturing experience, Pyrogreen’s equipment offers:

High energy efficiency

Combustible gases generated during carbonization can be used for power generation or heating, enabling energy self-sufficiency and additional revenue streams.

|

Diverse carbonizer types

Including externally heated rotary kilns, externally heated screw continuous carbonizers, and electrically heated continuous carbonizers, adaptable to various scales and feedstocks.

|

Carbon-negative emissions

Each ton of biochar sequesters approximately 3 tons of CO₂, with potential for carbon credit development.

|

Broad feedstock adaptability

Capable of processing diverse biomass materials, including agricultural residues, straw, and wood chips.

|

Parameter & Model of Biomass pyrolysis system

Pyrogreen Investment Returns

Value1: Carbon Credit Revenue (Voluntary Carbon Market)

Biochar carbon sequestration can persist for centuries, meeting international carbon credit standards (e.g., Verra, Gold Standard). Carbon credits can be sold at $20–50 per ton of CO₂ equivalent, offering ongoing revenue potential.

|

Value2: Biochar Sales Revenue

Biochar is widely used in:

Soil amendments: Enhancing soil fertility, water retention, and reducing fertilizer use.

Construction material additives: Improving the performance of concrete, asphalt, etc.

Metallurgical industry: Serving as a green reducing agent in steel production.

Environmental filtration:Applications in water treatment and air purification.

Market prices range from $500–$1,500 per ton depending on application.

|

Value3: Energy Byproduct Revenue

Combustible gases generated during carbonization can be used for power generation or heating, reducing operational costs or enabling electricity sales to the grid.

|

Value4: Policy Support & Subsidies

Governments in multiple countries provide tax incentives, subsidies, and green financing support for biomass energy and carbon removal projects, reducing investment risks.

|

FAQ

Q1: What is Biochar Carbon Removal?

A1: BCR is a negative emissions technology that converts biomass into biochar, allowing for carbon sequestration and the generation of tradable carbon credits.

Q2: How much carbon can be sequestered in biochar?

A2: Approximately 50% of biomass carbon can be stabilized in biochar, potentially generating valuable carbon credits over centuries.

Q3: How can companies use biochar to generate carbon credits?

A3: Companies can apply biochar to soil or sell it commercially. They can participate in carbon credit programs such as Verra’s VCS or Puro.earth.

.webp)