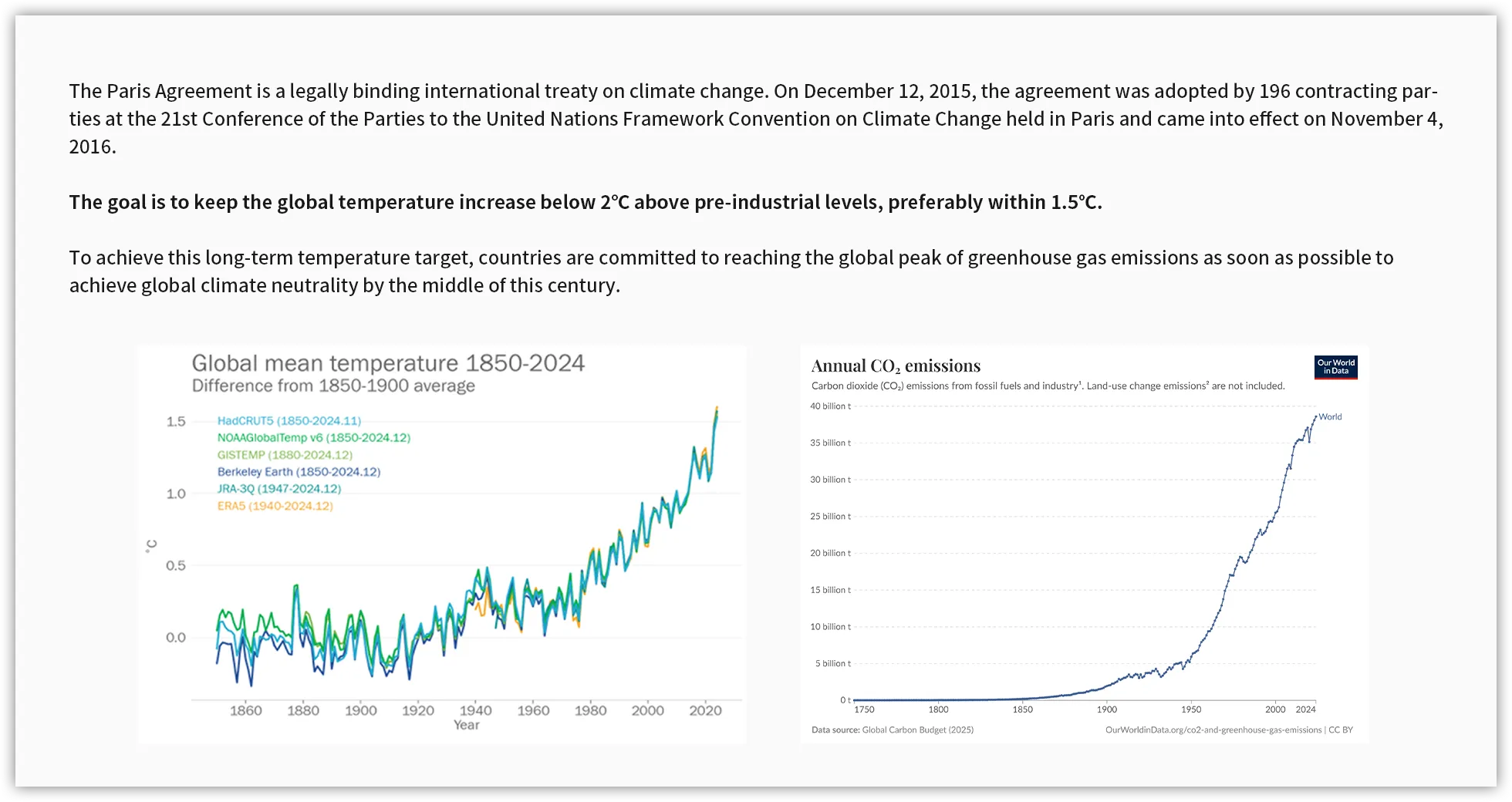

“Save the Earth, Start with Carbon Removal!”

Faced with the reality that carbon dioxide emissions will hit a record high, we must act urgently to save the future of our planet.

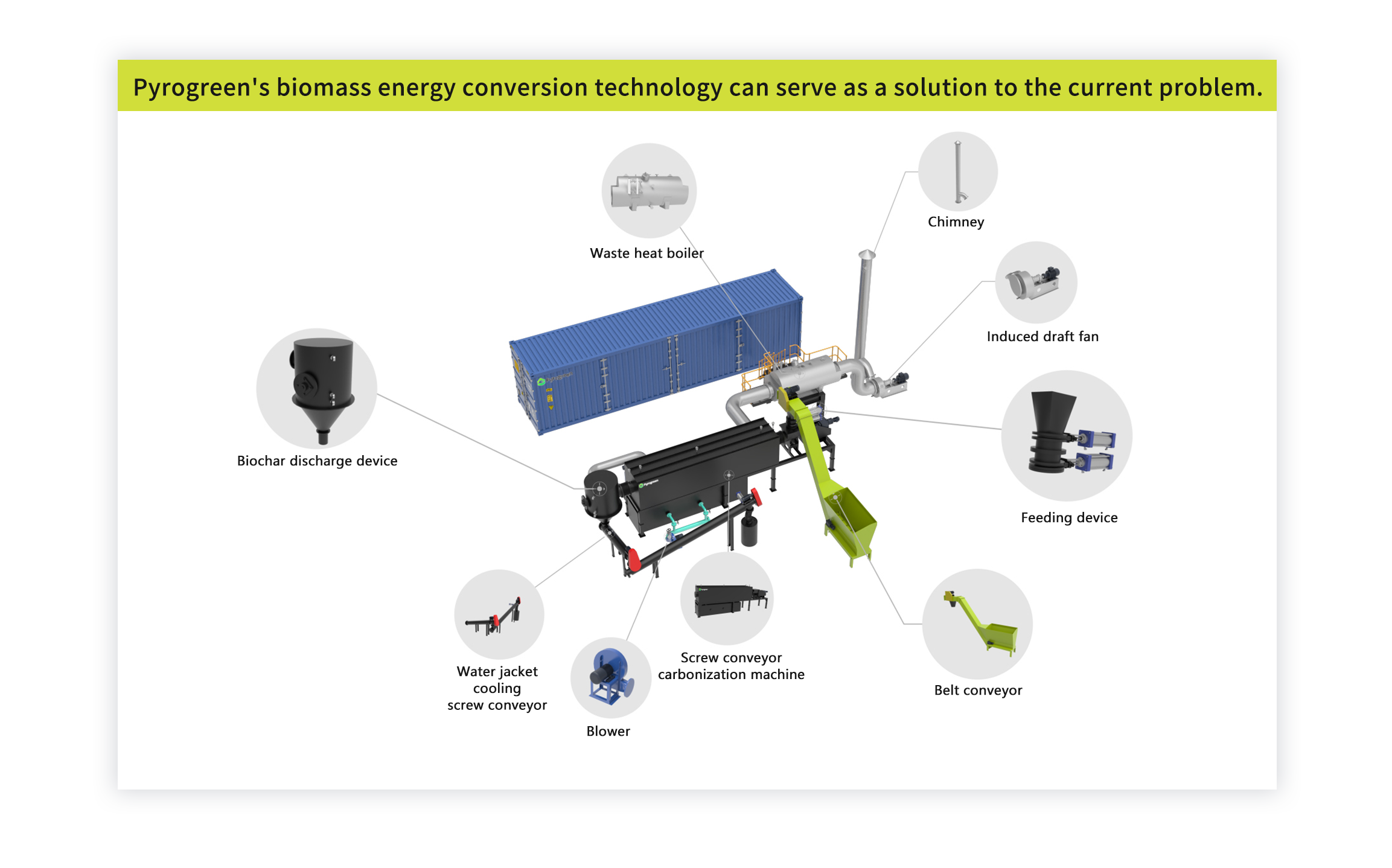

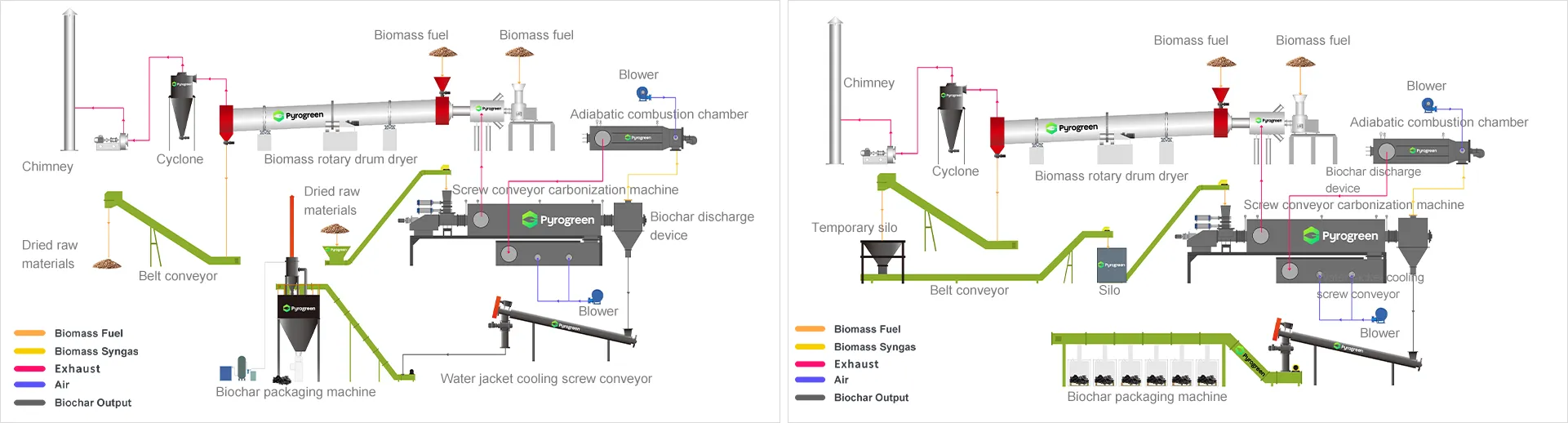

The Process

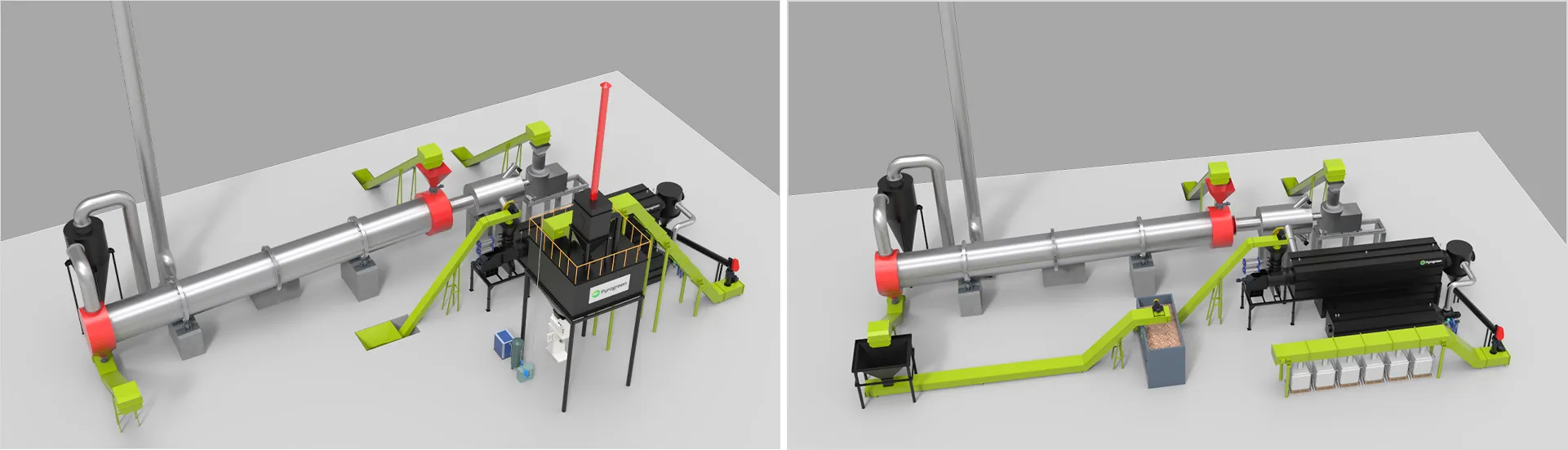

As a leader in advanced thermochemistry processing systems, Pyrogreen provides customized rotary kiln type and screw type carbonization/torrefaction system for the production of biochar from different kinds of biomass. Sometimes referred to as torrefaction, the pyrolysis of biomass into a high quality biochar product is a technical endeavor, requiring advanced knowledge of thermochemistry processing principles. Pyrogreen process experts would work with you to design this system around your unique source of material.

Advantage:

-

Modular Concept, easy transportation and installation.

-

High thermal efficiency and high biochar quality and quantity production.

-

No Tar and liquid waste production.

-

Fully Automation.

-

Extremly Low NOx, CO, Particle Emission.

Parameters |

Biomass Screw Conveyor Carbonizer |

Model |

BSCC1000 |

Feed Rate |

1m3/h(300kg) |

Footprint(L*H) |

16m*10.5m |

Working Mode |

Continuous |

Feed Requirements |

Size≤20mm(5-8mm is optimal),MC≤15% |

Consumption |

Indirect Heating Screw Conveyor Type |

Control Mode |

PLC Control System |

Material |

SS310S+SS304 |

Pressure |

Micro Negative Pressure |

Heating Fuel |

Diesel, natural gas, heavy oil, etc |

Heating Mode |

Indirect Heating |

Noise(dB) |

≤80 |

Cooling Mode |

Circulating Water Cooling |

Product Video

Pyrogreen Biomass Screw Conveyor Carbonization/Torrefaction System