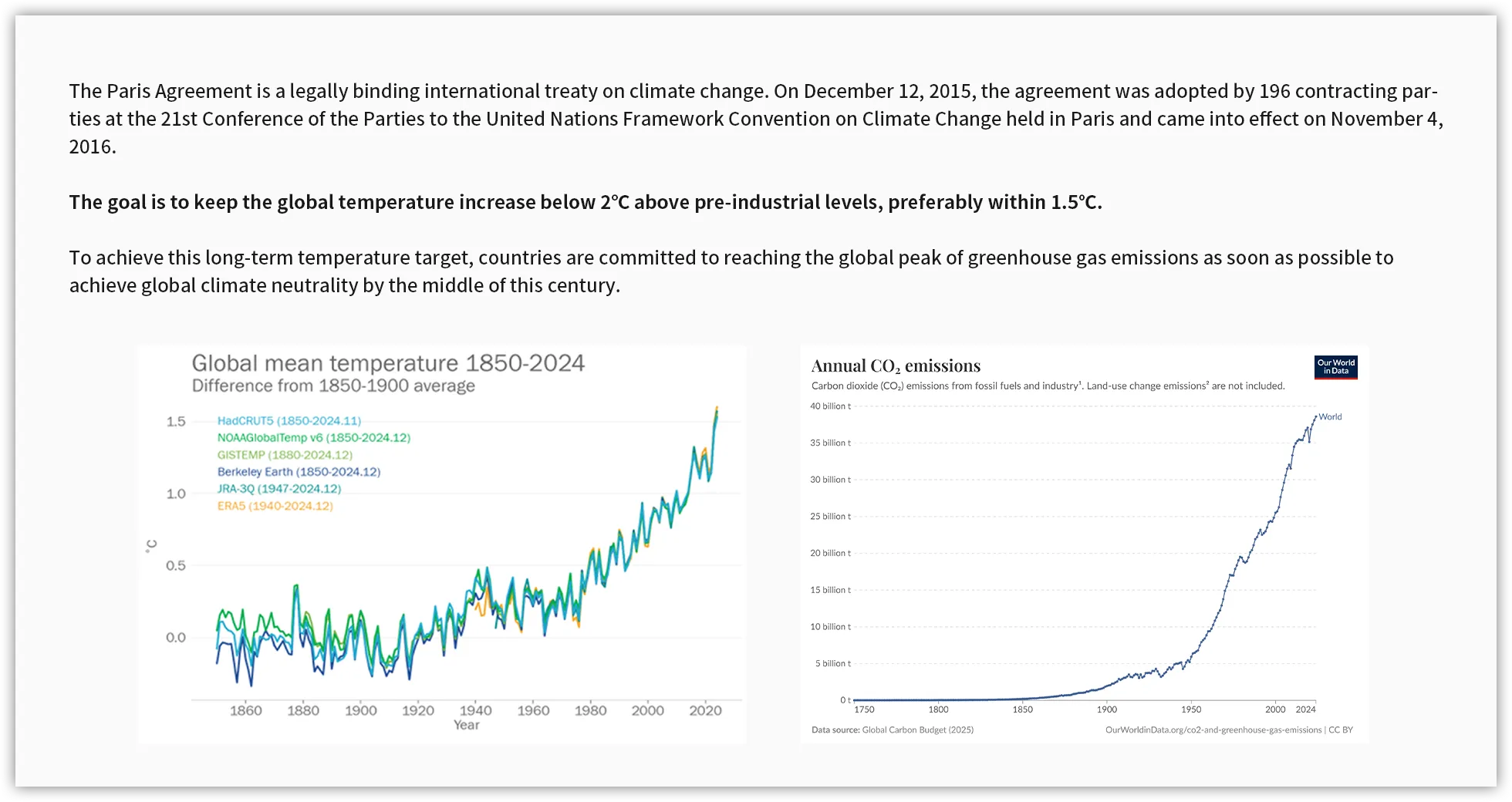

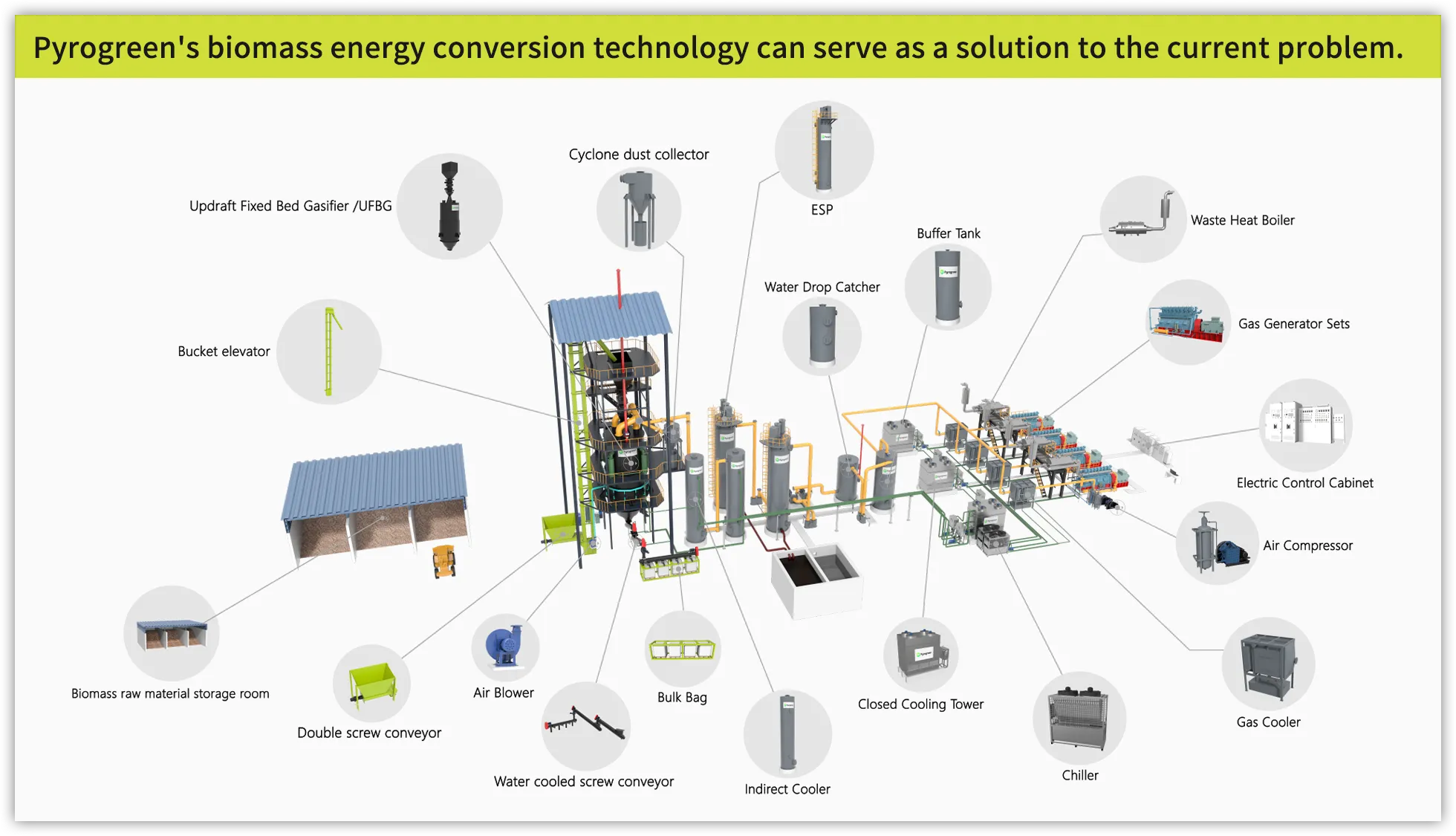

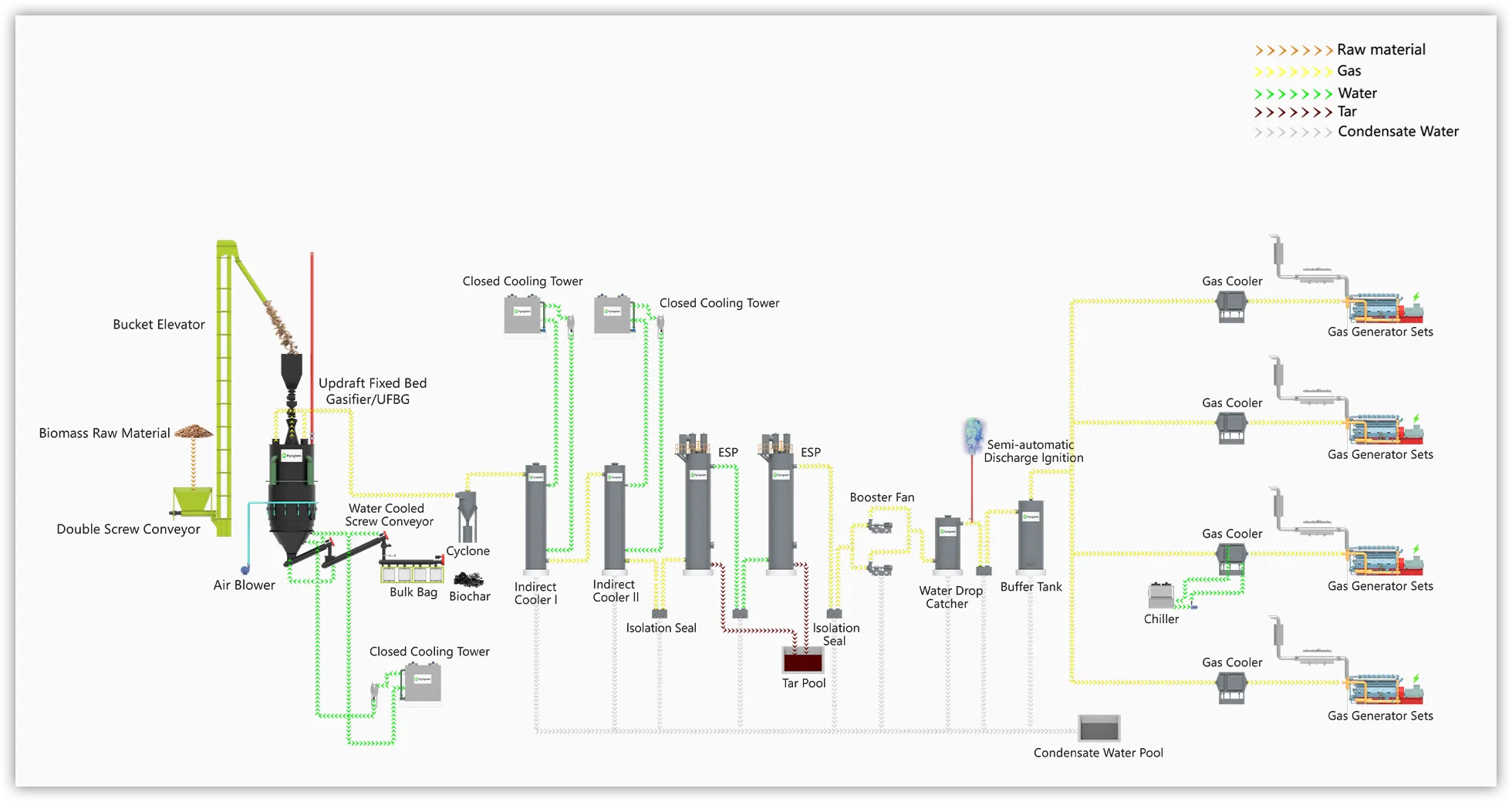

The Process

Agricultural and forestry waste such as wood chips, straw blocks, bamboo chips, corn cob, coconut shell, biomass pellet fuel and other biomass undergo pyrolysis gasification reaction in the gasifier with lean oxygen supply, producing combustible gas and biochar.It is then used as fuel in gas engine to generate electricity.The biochar is used in our daily life,industrial and agriculture production.

Technical Specification of UFBG Series Biomass Gasification Power Generation System |

|

Model |

WUFBG2400-5200 |

Gasifier Type |

Updraft Fixed Bed Gasifier |

Gas Purification System Type |

Dry Type |

Gasify Agent |

Steam and Hot Air |

Biomass Size Requirements |

Diameter: 20mm-80mm, Length: 20mm-80mm |

Biomass Moisture Requirements |

≥30%(WB) MAX55%(WB) |

Rated Gas Flow (Nm /hr) |

1.000-10,000 Per Module |

Average Gas Calorific Value(Kcal/Nm³) |

1200-1800 |

Rated Thermal Output after Purification Kcal/hr) |

1,200,000-12,000.000 |

For Power Generation |

500-5000kW Per Module |

Cold Gas Mode(After Purification) |

≥70-75% |

Temperature of Gas at Gasifier Outlet (°c) |

≤100℃ |

Temperature of Gas at ESP Outlet(°C) |

≤45°C |

Ash Removal |

Wet Ash / Dry Ash Removal System |

Product Video

Updraft Fixed-bed Carbonization Power Generation System