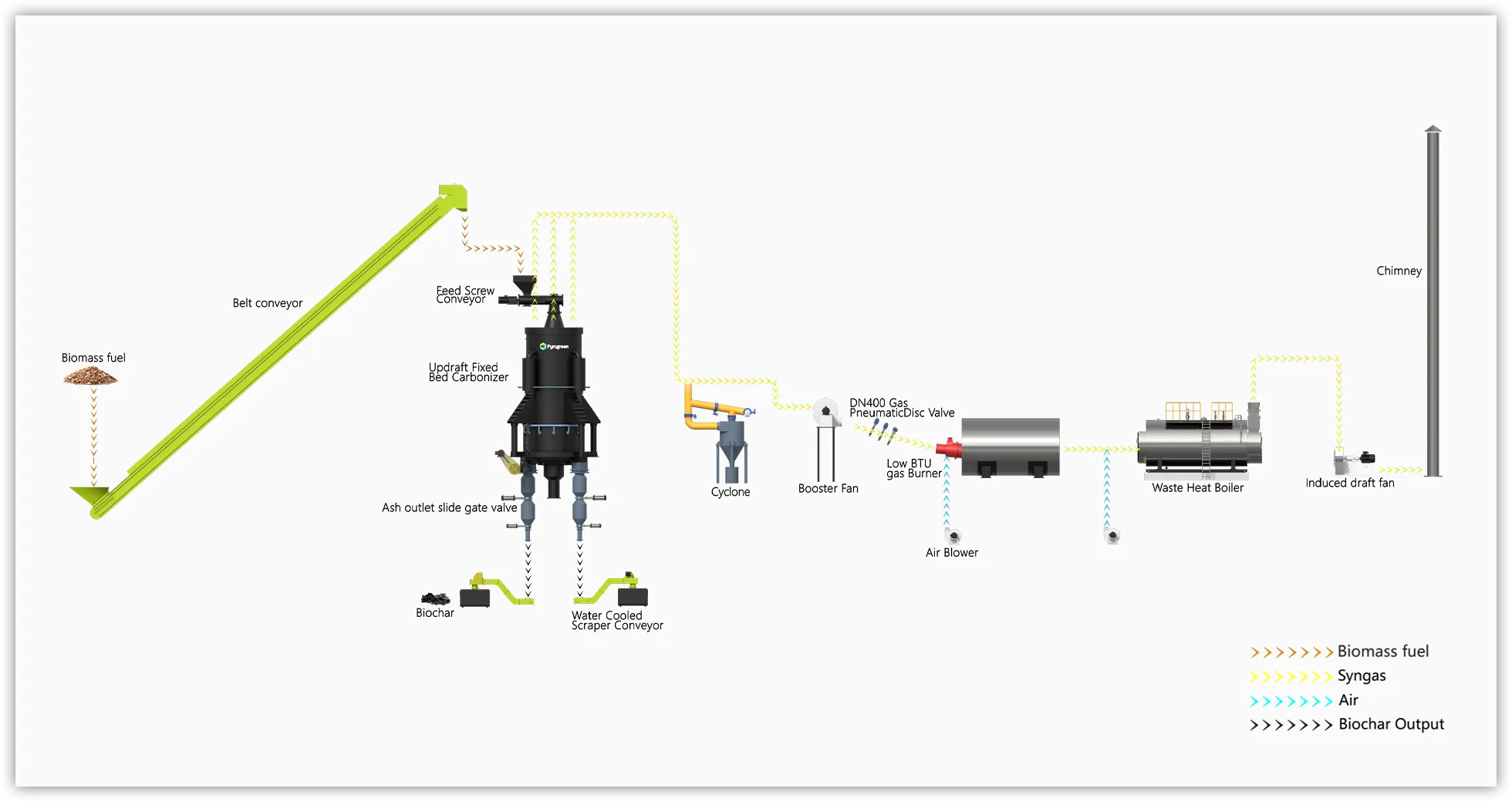

The Process

Agricultural and forestry waste such as wood chips, straw blocks, bamboo chips, corn cob, coconut shell, biomass pellet fuel and other biomass undergo pyrolysis gasification reaction in the gasifier with lean oxygen supply, producing combustible gas and biochar.The combustible gas converted from biomass is directly piped and burned in the adiabatic furnace to produce hot flue gas whose heat is exchanged in a waste heat boiler to produce steam (hot water) for residential or industrial use. The biochar is used in our daily life, industrial and agriculture production.

Parameters |

Biomass Downdraft Fixed Bed Carbonizer(DFBC-BC/B) |

|||||||

Model |

UFBC1000 |

UFBC1500 |

UFBC2000 |

UFBC2500 |

UFBC3000 |

UFBC4000 |

UFBC5000 |

|

Gasifier Type |

Updraft fixed Bed Carbonizer |

|||||||

Range of Biomass Input |

Wood chips, bamboo chips, coconut shell and etc. |

|||||||

Size Requirement |

20-100 mm |

|||||||

Moisture Requirement |

≤30% |

|||||||

Biomass Consumption |

1000Kg/H |

1500Kg/H |

2000Kg/H |

2500Kg/H |

3000Kg/H |

4000Kg/H |

5000Kg/H |

|

Heat Value of Gas |

>1200 Kcal/Nm3 |

|||||||

Biochar Output(Kg/H) |

≤150 |

≤225 |

≤300 |

≤375 |

≤450 |

≤600 |

≤750 |

|

Heat |

Kcal |

≤1,764,706 |

≤2,647.059 |

≤3,529,412 |

≤4,411,765 |

≤5,294,118 |

≤7.058,824 |

≤8,823.529 |

KW |

≤2,052 |

≤3,078 |

≤4,104 |

≤5,130 |

≤6,156 |

≤8,208 |

≤10,260 |

|

Product Video

Updraft Fixed-bed Carbonizer