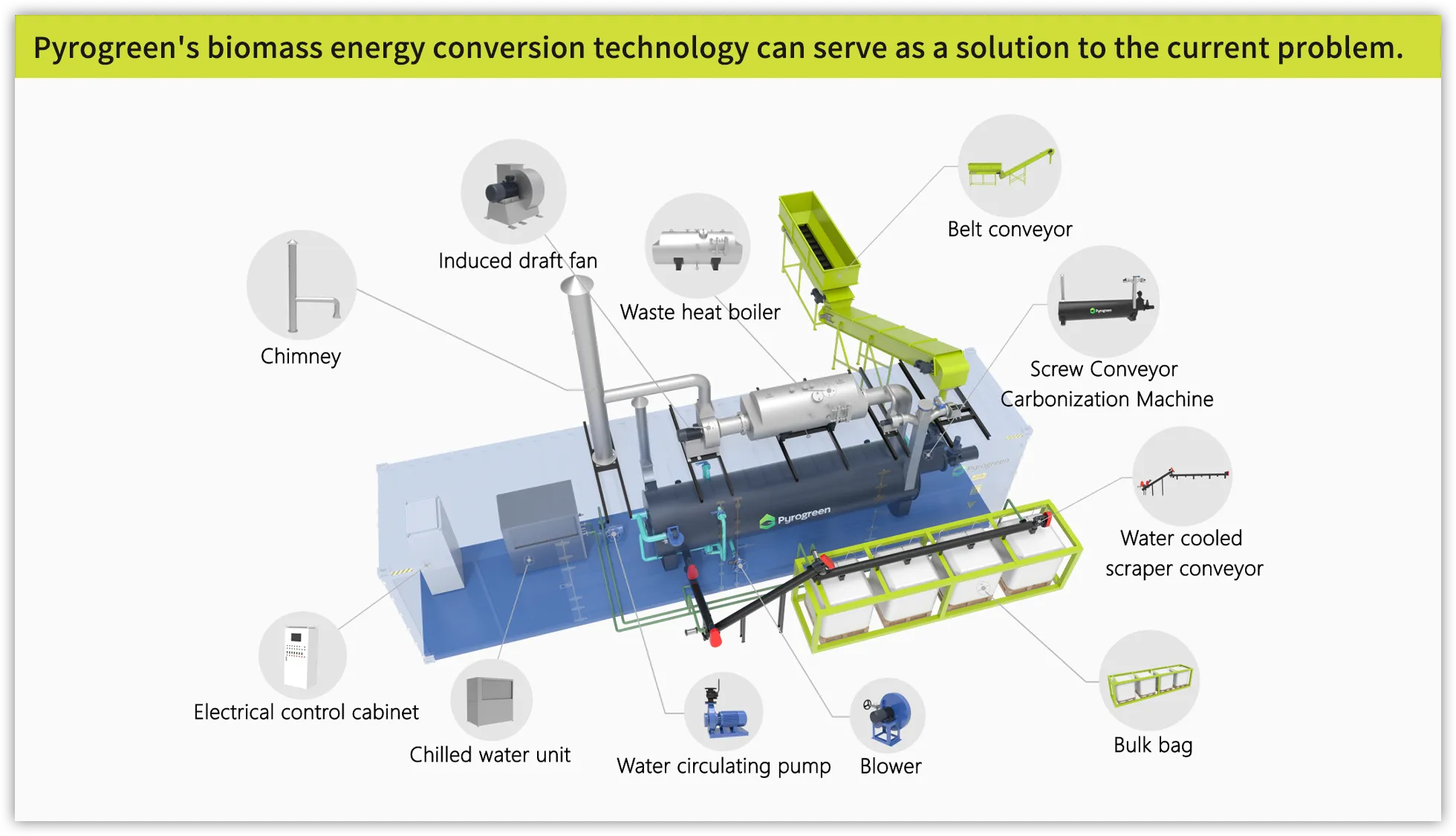

The Process

As a leader in advanced thermochemistry processing systems, Pyrogreen provides customized rotary kiln type and screw type carbonization/torrefaction system for the production of biochar from different kinds of biomass. Sometimes referred to as torrefaction, the pyrolysis of biomass into a high quality biochar product is a technical endeavor, requiring advanced knowledge of thermochemistry processing principles. Pyrogreen process experts would work with you to design this system around your unique source of material.

Advantage:

-

Modular Concept, easy transportation and installation.

-

High thermal efficiency and high biochar quality and quantity production.

-

No Tar and liquid waste production.

-

Fully Automation.

-

Extremly Low NOx, CO, Particle Emission.

Pyrogreen series |

2T |

4T |

6T |

8T |

10T |

|

Dimensions |

Diameter (mm) x length (mm) |

⌽1200x7500 |

⌽1600x7500 |

⌽1800x10500 |

⌽2000x13000 |

⌽2400x13000 |

Feed motor power (kW) |

1.1kw |

3kw |

4kw |

7.5kw |

11kw |

|

Feed screw diameter (mm) |

⌽219 |

⌽219 |

⌽325 |

⌽377 |

⌽377 |

|

Thermometer selection |

Wireless |

Wireless |

Wireless |

Wireless |

Wireless |

|

Silo |

Level gauge |

Rotary |

Rotary |

Rotary |

Rotary |

Rotary |

Discharge |

Rotary valve diameter |

⌽219 |

⌽219 |

⌽325 |

⌽377 |

⌽377 |

Cooling |

Cooling system |

Spiral cooler |

Spiral cooler |

Spiral cooler/Platetype slag cooler |

Spiral cooler/Platetype slag cooler |

Spiral cooler/Platetype slag cooler |

Rated fuel feed rate (moisture content <18%) |

0.8 |

1.6 |

2.4 |

3.2 |

4 |

|

Rated steam output (m3/h) |

1000 |

2000 |

3000 |

4000 |

5000 |

|

Note:lf there are any deviations in the above data, please refer to the actual product and market conditions. The core components are all made of 310s |

||||||