Biomass Pyrolysis: Slow Pyrolysis Systems for Biochar Production | Pyrogreen

Aug 12, 2025

Biomass Pyrolysis: Slow Pyrolysis Systems for Biochar Production | Pyrogreen

Definition: Biomass pyrolysis is a carbon-neutral process that converts waste biomass into three main products under oxygen-limited conditions:

1. Biochar: a stable carbon material ideal for soil amendment and carbon sequestration.

2. Tar: a liquid by-product that can be processed into bio-oil.

3. Syngas: a renewable energy gas that can be used for heat and power generation.

Pyrogreen's slow pyrolysis systems provide an efficient solution for reducing carbon dioxide emissions while turning biomass waste into valuable energy and carbon-negative biochar.

The Biomass Pyrolysis Process

|

Step |

Temperature Range |

Reactions | Product Changes |

Drying |

100–150°C | Moisture evaporation | Wet biomass → Dry biomass |

Pre-carbonization |

50–300°C | Hemicellulose decomposition | Releases CO₂, acetic acid, etc. |

Core Pyrolysis Stage |

300–600°C | Cellulose/lignin breakdown (key phase) | Produces biochar (solid), tar (liquid), syngas (gas) |

Cooling |

<100°C | Reaction termination | Biochar stabilization |

Types of Biomass Pyrolysis

A. Classification by Pyrolysis Conditions

(1) Slow Pyrolysis

Slow Pyrolysis: Optimized for high-quality biochar production, this method uses low heating rates (<400°C) over extended periods (hours to days), making it ideal for carbon sequestration projects. Also known as biomass carbonization.

(2) Conventional Pyrolysis

Biomass feedstock is processed in standard pyrolysis equipment at temperatures below 500°C with moderate heating rates and residence times of 0.5–5 seconds. This method produces gas, liquid, and solid products in roughly equal proportions.

(3) Fast Pyrolysis

In fast pyrolysis, finely ground biomass is fed into specialized reactors. The material undergoes instantaneous gasification at atmospheric pressure with ultra-high heating rates, very short residence times, and moderate pyrolysis temperatures (500–650°C). The vapors are then rapidly condensed to maximize liquid bio-oil yield.

B. Classification by Operation Mode

(1) Batch Pyrolysis Reactor

Batch pyrolysis refers to a process where each production cycle in an enclosed reactor requires separate stages: loading, preheating, reaction, cooling, and unloading. Each stage demands dedicated time, and operators can only initiate the next batch after completing the current cycle.

As a common configuration in biomass pyrolysis systems, batch reactors process a fixed quantity of feedstock per operation until completion. These units offer straightforward operation, relatively low cost, and high flexibility. However, they suffer from significant energy consumption (due to repeated heating/cooling cycles), heavy reliance on manual labor, high worker intensity, poor continuous production capability, and limited throughput.

Working Principle: Single feedstock load → Sealed oxygen-free heating → Product retrieval after cooling.

Advantages: Simple structure, low capital investment, ideal for small-scale operations.

(2) Semi-Continuous Pyrolysis Reactor

Semi-continuous systems bridge the gap between batch and fully continuous reactors. They allow feedstock input without cooling downtime, minimizing energy waste from temperature cycling. The enclosed feeding and discharge processes enhance environmental performance by reducing exhaust leakage. While still requiring manual intervention for material changes or product collection, these units demonstrate higher production efficiency and reduced labor intensity compared to batch systems.

(3) Fully Continuous Pyrolysis Reactor

Working Principle: PLC-controlled continuous operation integrating feeding, reaction, and residue discharge (e.g., screw conveyor + fluidized bed design).

Advantages: High throughput, reduced energy consumption, engineered for industrial-scale deployment.

Pyrogreen Fully Automatic Biomass Pyrolysis Machine:Screw Conveyor Carbonization/Torrefaction System Rotary Kiln Carbonization/Torrefaction System

How Does a Pyrolysis System Work? (Pyrogreen Example)

PyroGreen: Specialized in Slow Pyrolysis Technology

Pyrogreen specializes in slow pyrolysis carbonization and torrefaction pretreatment, delivering high-efficiency, eco-friendly solutions that convert biomass into energy and high-value biochar.

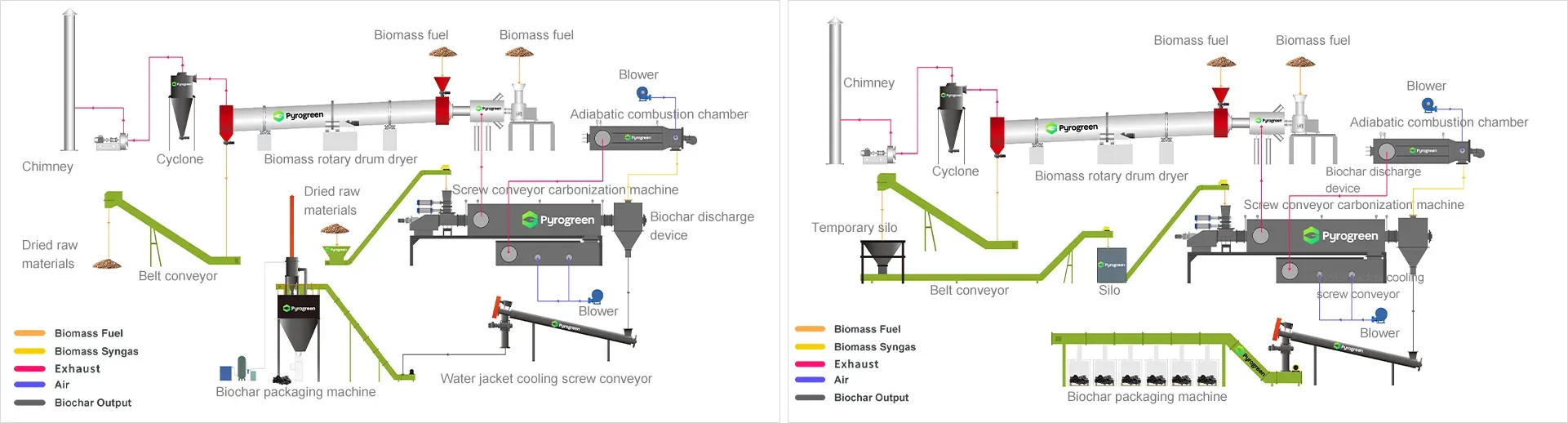

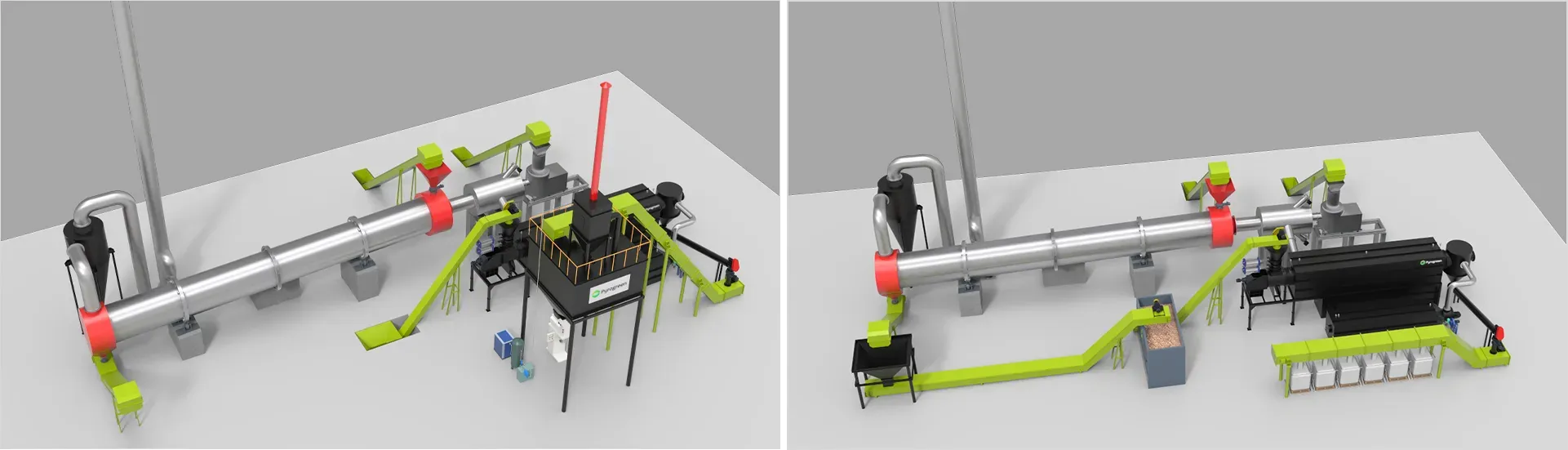

1:Screw ConveyorCarbonization/Torrefaction System(Click for more information)

Biomass feedstock enters via a screw conveyor → Thermally decomposed in an oxygen-free chamber (carbonization reactor)

→ Hot gases routed to waste heat boiler → Biochar cooled via water-cooled screw/scraper conveyors and cooling tower → Final discharge.

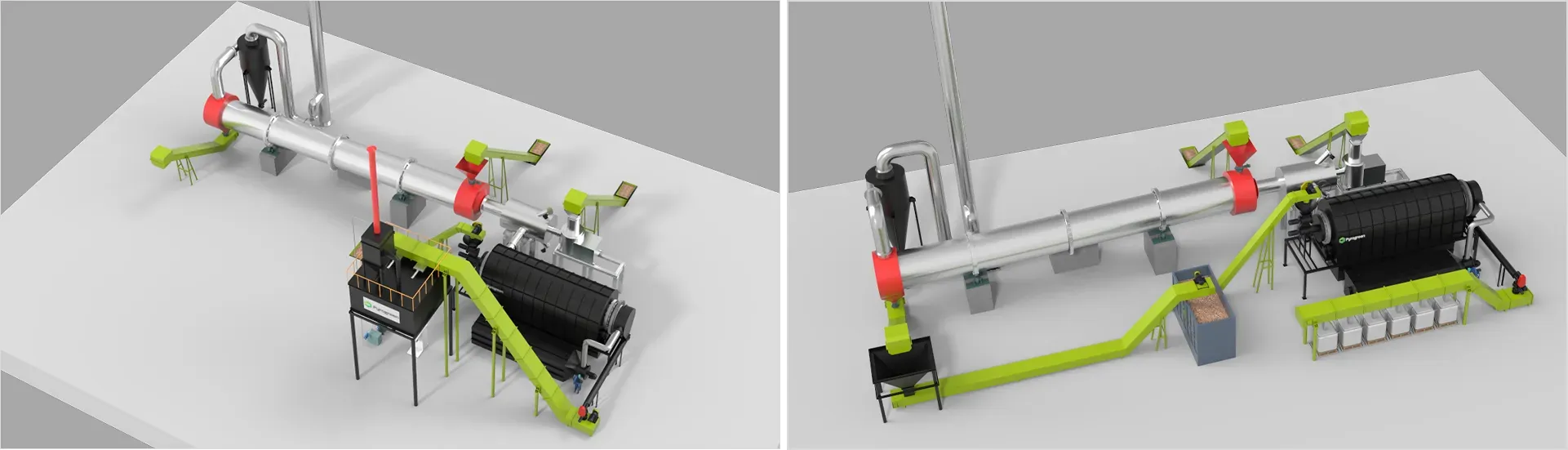

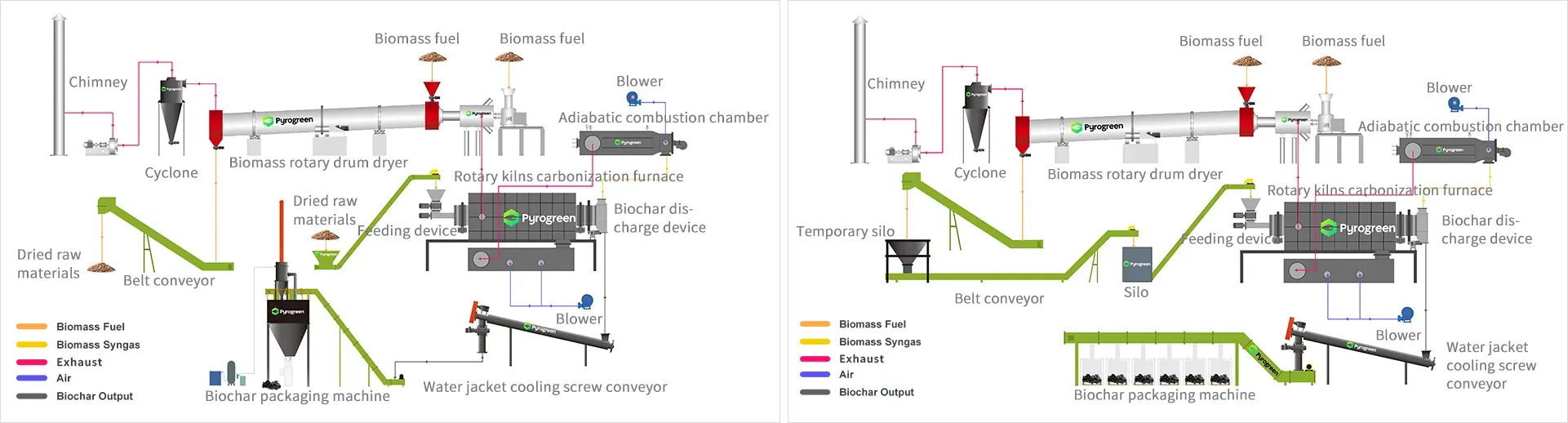

2:Rotary KilnsCarbonization/Torrefaction System(Click for more information)

Biomass fed into rotating kiln → Indirect heating by combustion chamber + induced draft fan control → Exhaust gases processed in waste heat boiler and chimney → Biochar cooled via scraper conveyor + cooling water tank → Output.

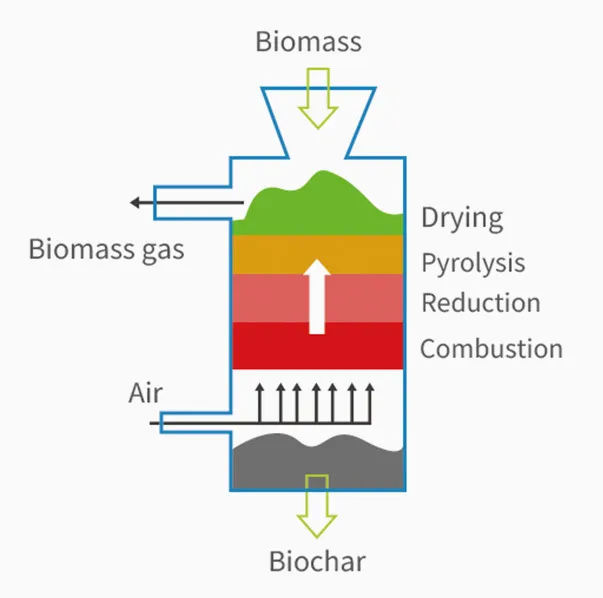

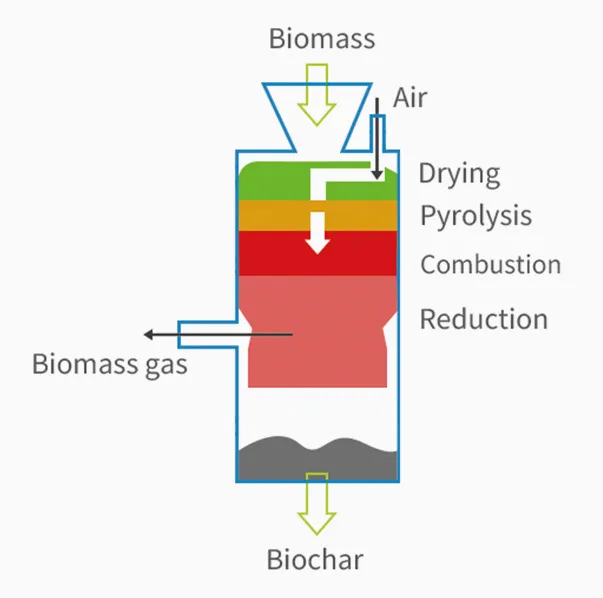

3:Updraft Fixed Bed Carbonization System(Click for more information)

Biomass updraft fixed bed carbonizer is a machine that converts biomass such as wood chips, bamboo chips,coconut shell, fruit shells, under a lean oxygen atmosphere into biochar and combustible gas which could be piped to heat supply system as gas fuel.

Biomass raw materials (such as wood chips and rice husks) enter the system via a belt conveyor.

The raw materials are heated in the decomposition furnace in the absence of oxygen, causing pyrolysis. The resulting gases are removed from the system by a cyclone dust collector.

The hot biochar is cooled by a water-cooled screw conveyor in a cooling tower and cooling water pool.

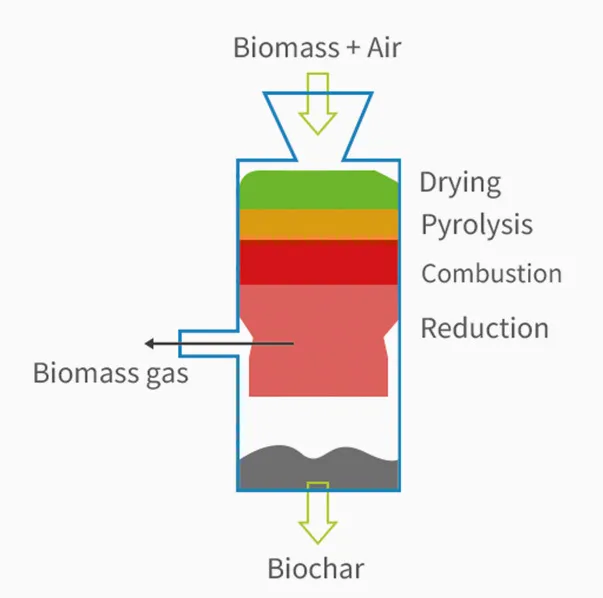

4:Downdraft Fixed BedCarbonization System(DFBC-BC-S)(Click for more information)

This system employs downdraft fixed-bed gasification technology to convert biomass feedstock into biochar and combustible gas while achieving thermal energy recovery.

Feedstock Handling:Biomass materials (e.g., wood chips, rice husks, straw) are initially stored in the raw material warehouse and conveyed into the system via transportation equipment (e.g., belt conveyors).

Gas Cleaning:The raw gas passes through:Pulse-jet dust collectors,Waste gas precipitators.These components remove tar and particulate matter to ensure safe downstream operation.

Biochar Cooling & Output:High-temperature biochar is gradually cooled via a water-cooled screw conveyor to prevent spontaneous combustion and maintain product quality.A recirculating water system further reduces the biochar temperature, yielding stable, ready-to-use biochar.

5:Downdraft Fixed BedCarbonization System(DFBC-BC-B)(Click for more information)

Agricultural and forestry waste such as wood chips, bamboo chips, corn cob, coconut shell and other biomass undergo pyrolysis gasification reaction in the carbonizer with lean oxygen supply, producing combustible gas and biochar. The combustible gas converted from biomass is directly piped and burned in the adiabatic furnace to produce hot flue gas whose heat is exchanged in a waste heat boiler to produce steam (hot water) for residential or industrial use.

Core Applications of Pyrolysis Products

|

Application |

Specific Use |

Benefits |

|

Soil Amendment |

Biochar added to farmland/gardens |

Improves water retention, reduces fertilizer use, enhances soil fertility. |

|

Construction Material |

Biochar mixed into concrete |

Increases compressive strength, creates "carbon-negative concrete." |

|

Industrial Feedstock |

Replaces coke in green steel production |

Lowers reliance on fossil fuels, cuts carbon footprint. |

|

Carbon Trading Asset |

Biochar in voluntary carbon markets |

1 ton biochar ≈ 3 tons CO₂ sequestered; generates sellable carbon credits. |

The Carbon Sequestration Logic

Why Pyrolysis is a Carbon Solution

|

Method |

Oxygen |

Emissions |

Main Outputs |

Carbon Fate |

|

Combustion |

High oxygen |

High CO₂ |

Ash + heat |

Atmosphere (carbon added) |

|

Gasification |

Limited oxygen |

Moderate CO |

Syngas + low-grade char |

Partly released to atmosphere |

|

Pyrolysis |

Zero oxygen |

Near-zero CO₂ |

Biochar + tar + gas |

Locked in soil (1,000+ years) |

PyroGreen: Specialized in Slow Pyrolysis Technology

Pyrogreen specializes in slow pyrolysis carbonization and torrefaction pretreatment, delivering high-efficiency, eco-friendly solutions that convert biomass into energy and high-value biochar.Explore Biochar Solutions : Contact Pyrogreen to Turn Your Biomass Waste into Carbon-Negative Products.