Biochar Pyrolysis Equipment & Biomass Carbonization Systems | Turnkey Solutions by PyroGreen

Aug 13, 2025

Biochar Pyrolysis Equipment & Biomass Carbonization Systems | Turnkey Solutions by PyroGreen

Biochar Production Systems

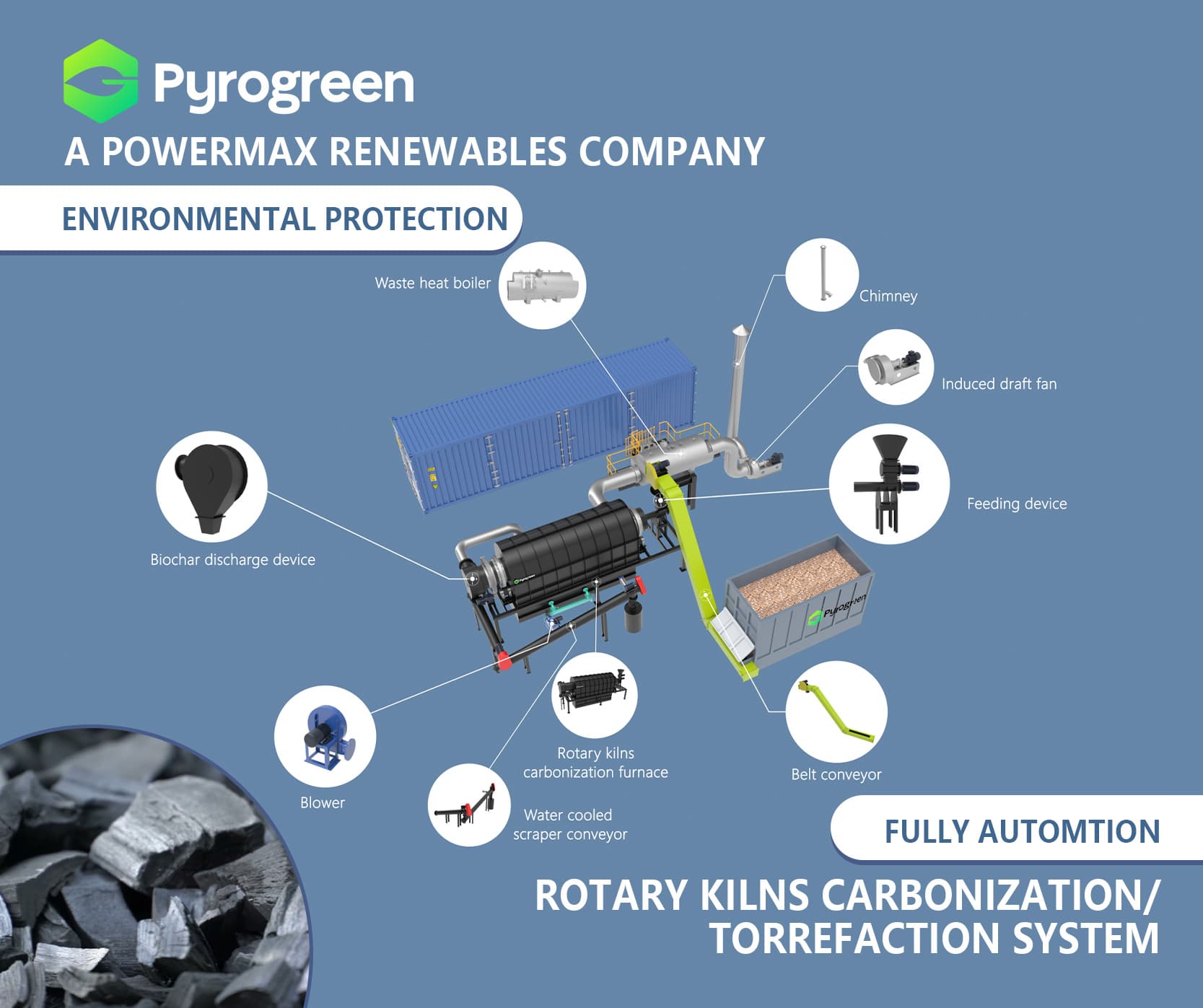

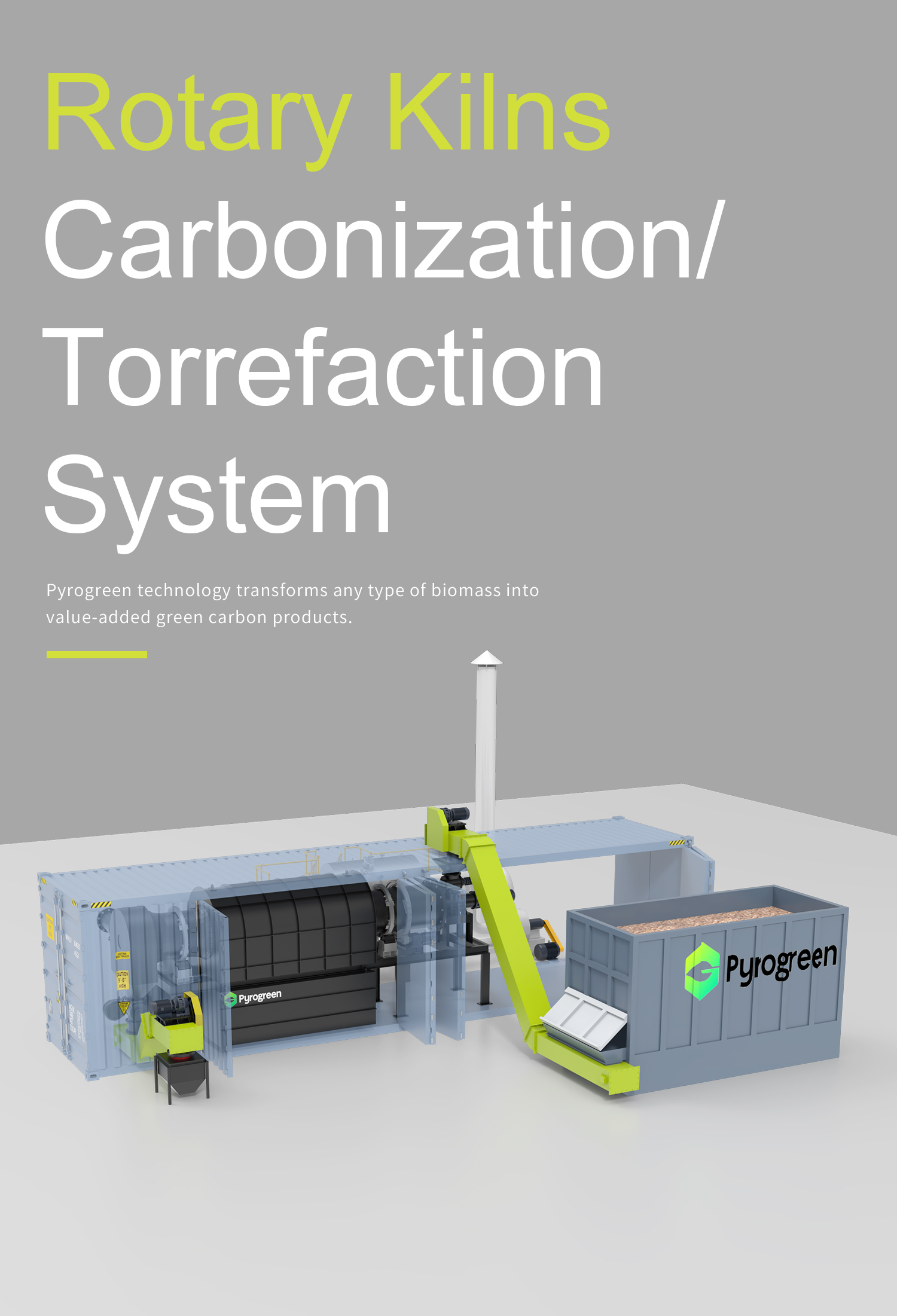

Biochar pyrolysis equipment (also called biochar production systems or biomass carbonization equipment) converts biomass feedstocks—such as agricultural residues, forestry waste, and livestock manure—into high-quality biochar and syngas under oxygen-limited or anaerobic conditions. These systems ensure efficient biomass conversion, enabling renewable energy recovery and the generation of carbon credits through biochar production.

A complete biochar production system comprises four core modules:

| Feedstock Pretreatment Unit | Pyrolysis Reactor | Product Separation & Collection System | Emission Control System |

Biomass Pretreatment System

Function: Prepares raw biomass through crushing, drying, and homogenization to ensure consistent pyrolysis efficiency.

Pyrolysis Reactor

Core Process: Pyrolysis occurs at 300–800°C in oxygen-deprived environments, decomposing biomass into:

Critical Parameters:

Temperature: Determines biochar porosity & carbon stability

Heating Rate: Slow pyrolysis (biochar-focused) vs. fast pyrolysis (bio-oil-focused)

Residence Time: Ensures complete decomposition

Byproduct Recovery Systems |

|

| Syngas Recycling: | Captures H₂/CH₄ for process heating or power generation |

| Condenser: | Recovers liquid bio-oil |

Emission Control System |

Removes tars, particulates, and harmful gases (NOₓ/SOₓ) to meet EPA/EU emissions standards. |

Smart Control System |

Real-time monitoring of temperature, pressure, and oxygen levels.

|

| Automated operation with PLC/HMI interfaces |

|

Competitive Advantages & Revenue Models

Multi-Feedstock Compatibility of Biochar Pyrolysis Equipment

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

Scalable Solutions |

Capacity: 50 kg/hr to 5 MT/hr(Modular systems for higher throughput ) | ||

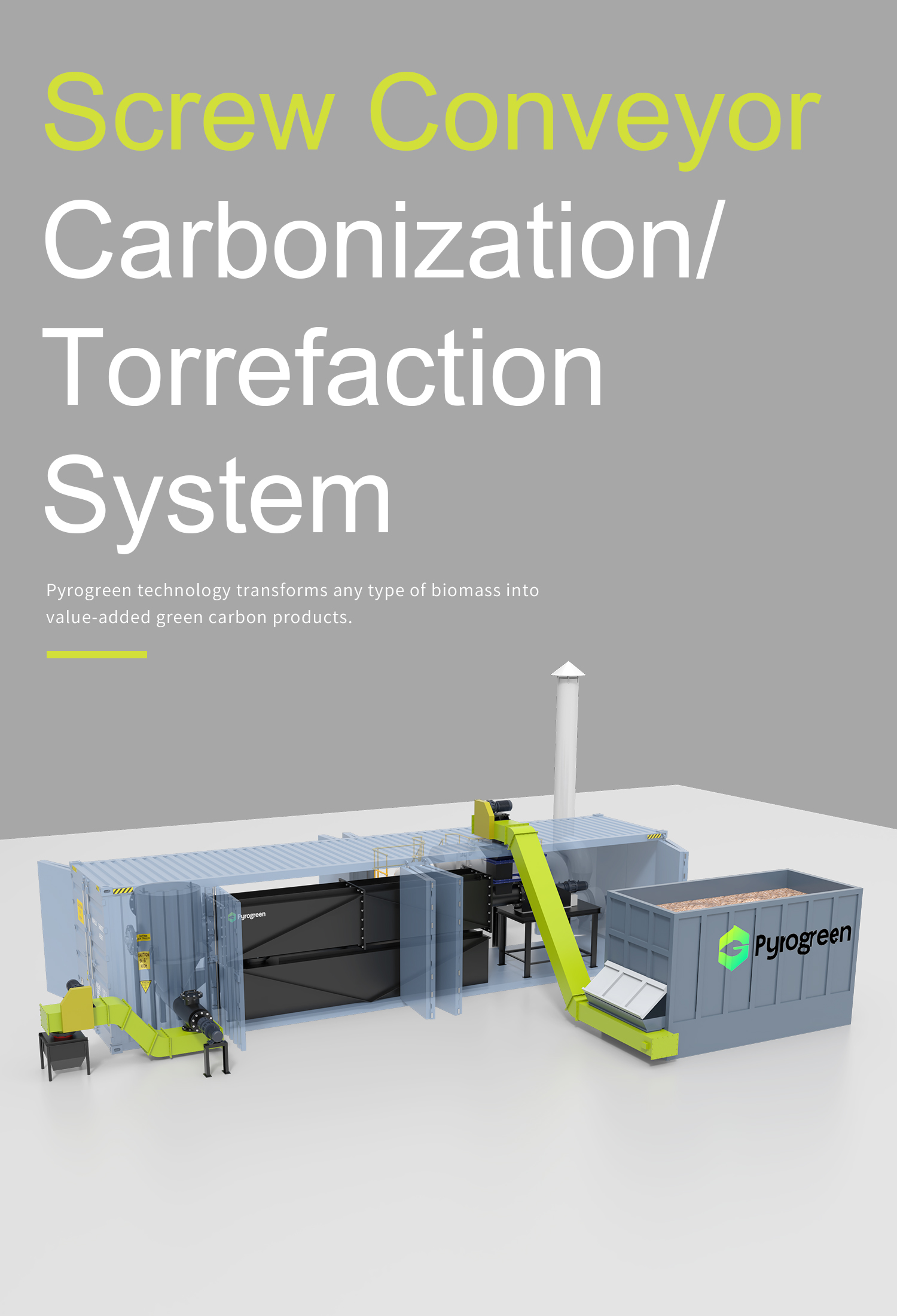

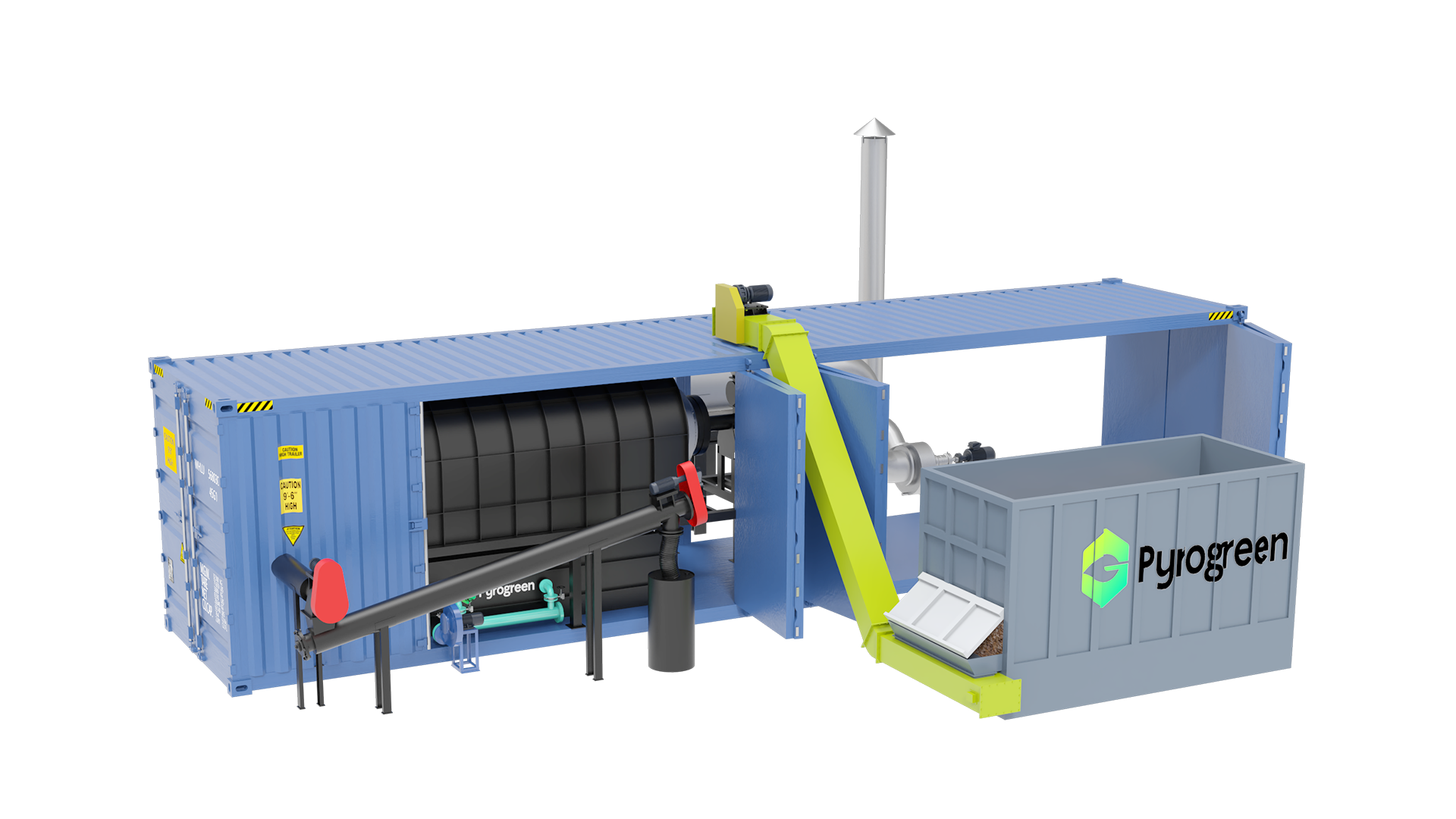

Modular Containerized Units |

Ideal for small farms/distributed production | ||

Clean Production Compliance |

GHG Control: Low-NOx sealed combustion minimizes methane emissions | ||

| Exhaust Treatment: Integrated scrubbing/cooling for PM/VOCs removal | |||

Profit Streams |

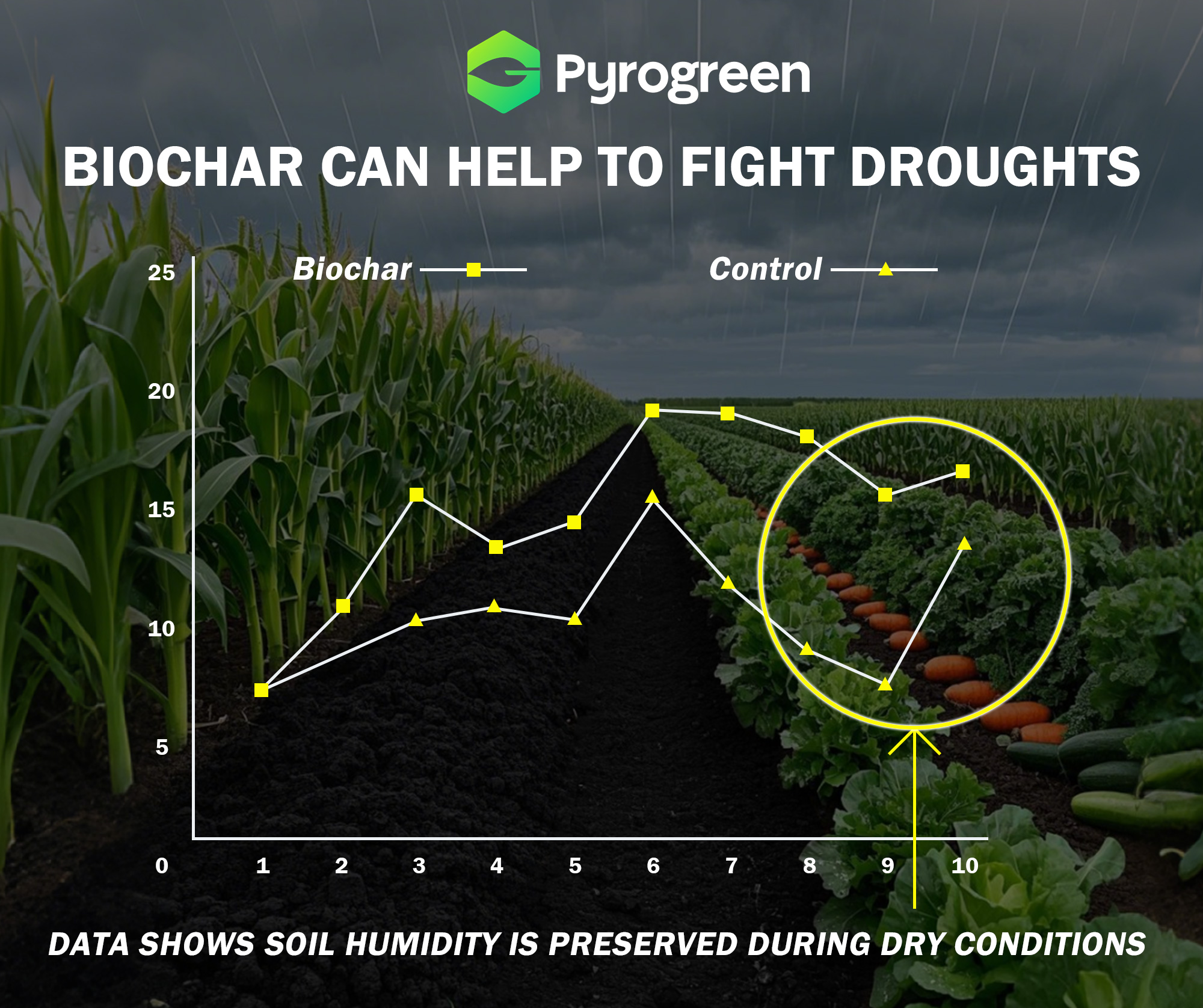

Biochar Sales: Premium soil amendment for agriculture/environmental remediation |

||

| Energy Byproducts: Syngas/bio-oil monetization |

|||

|

Carbon Credits: Recognized under international standards (Verra, Puro.earth), enhancing ROI |

|||

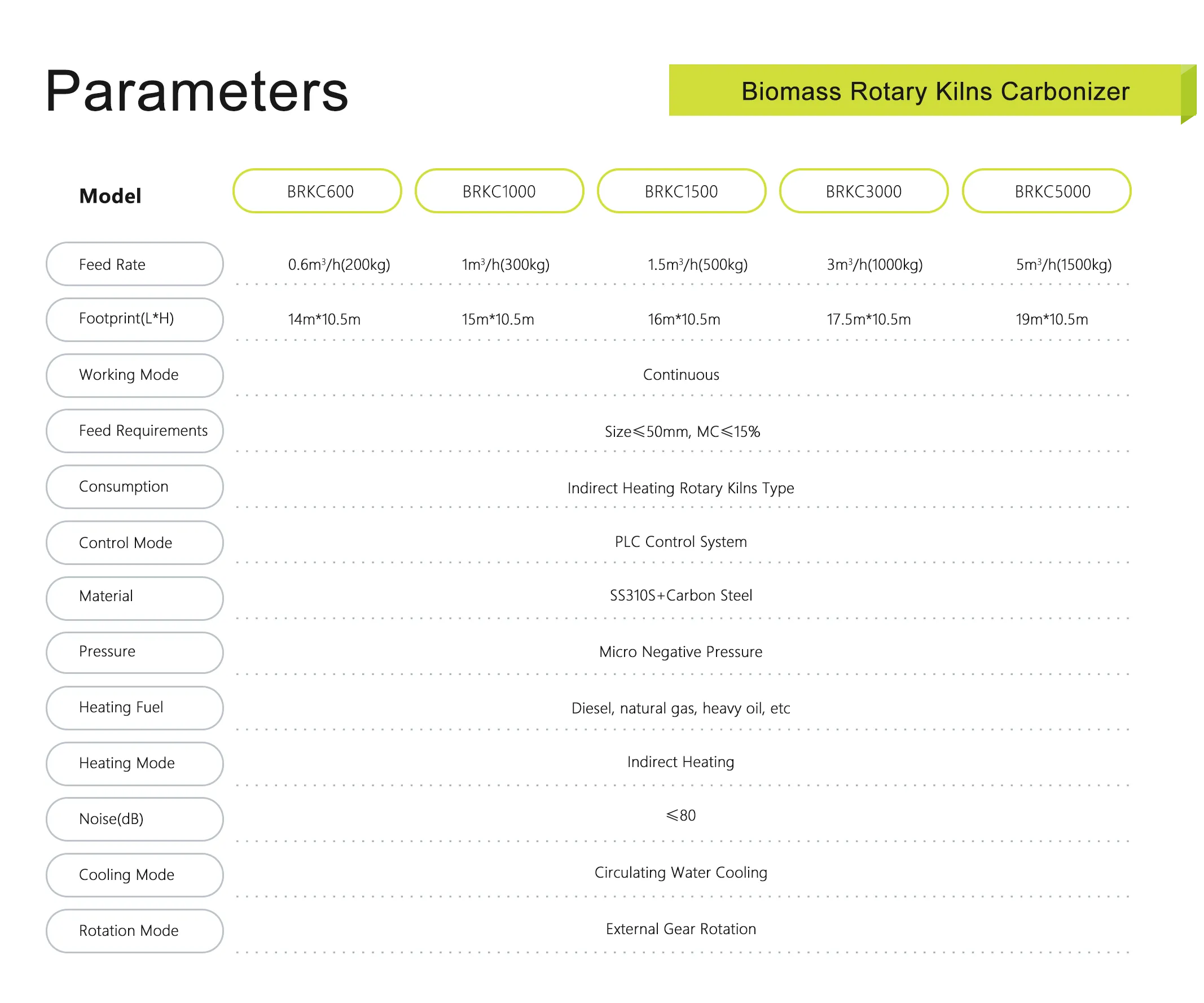

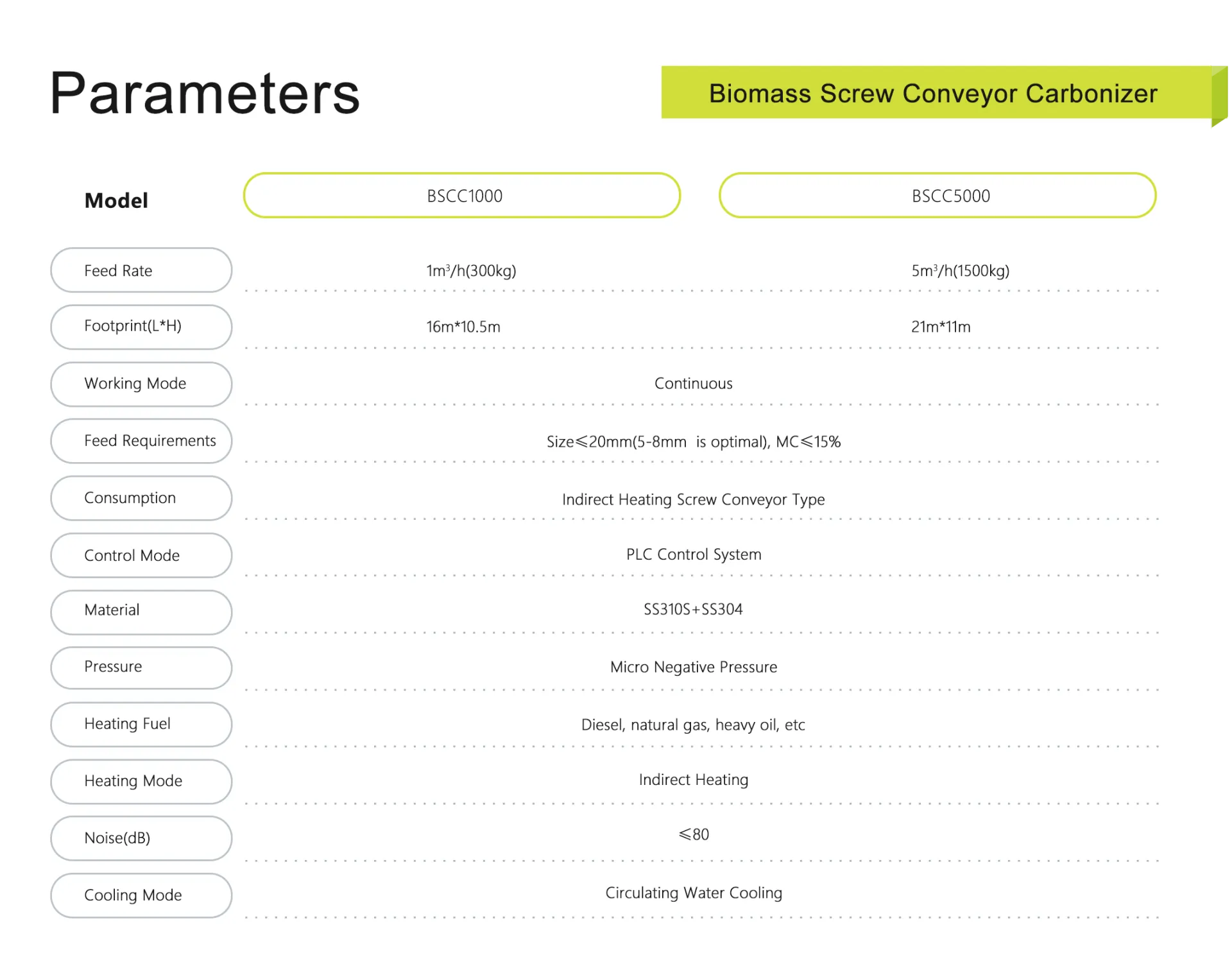

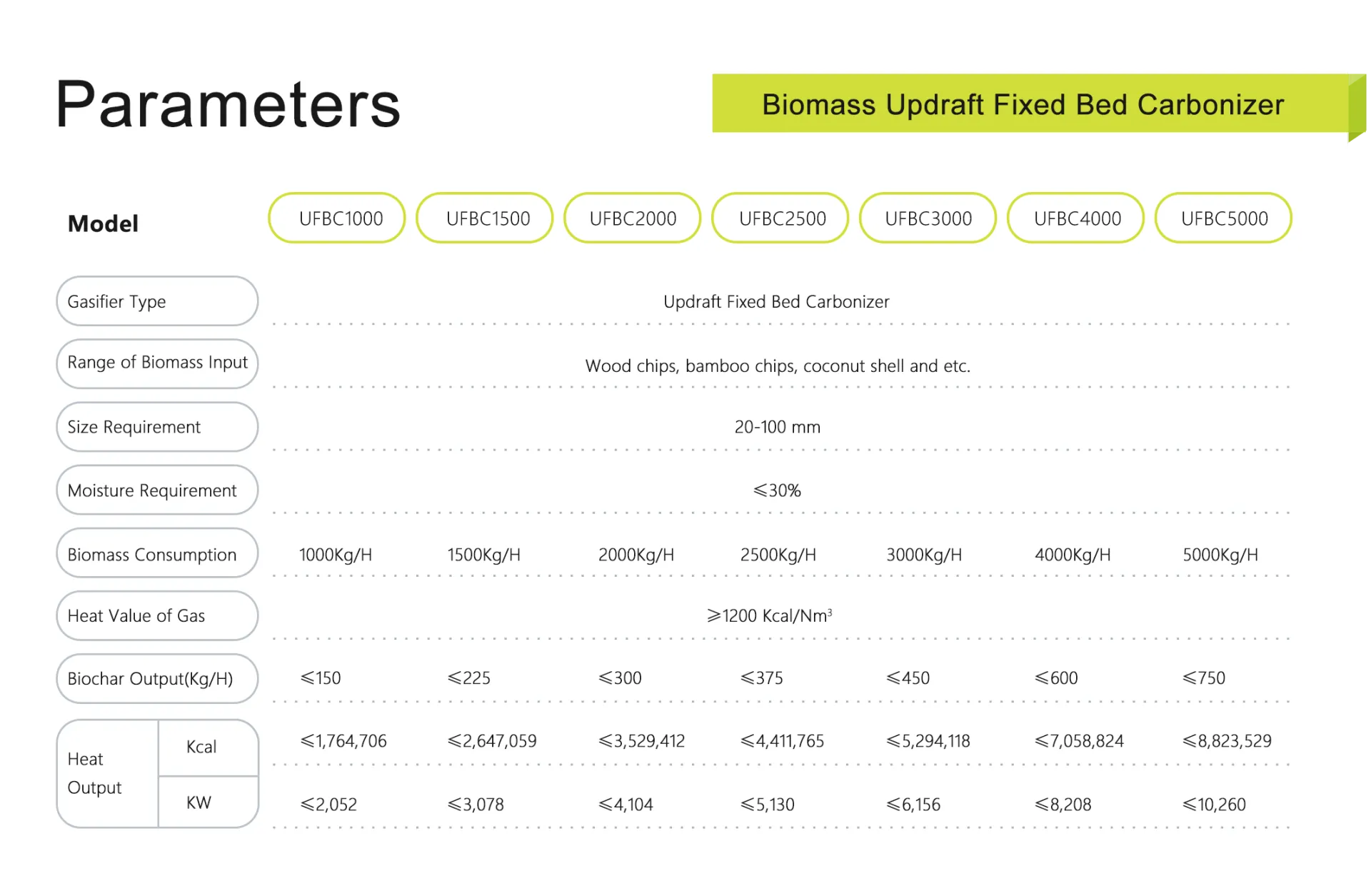

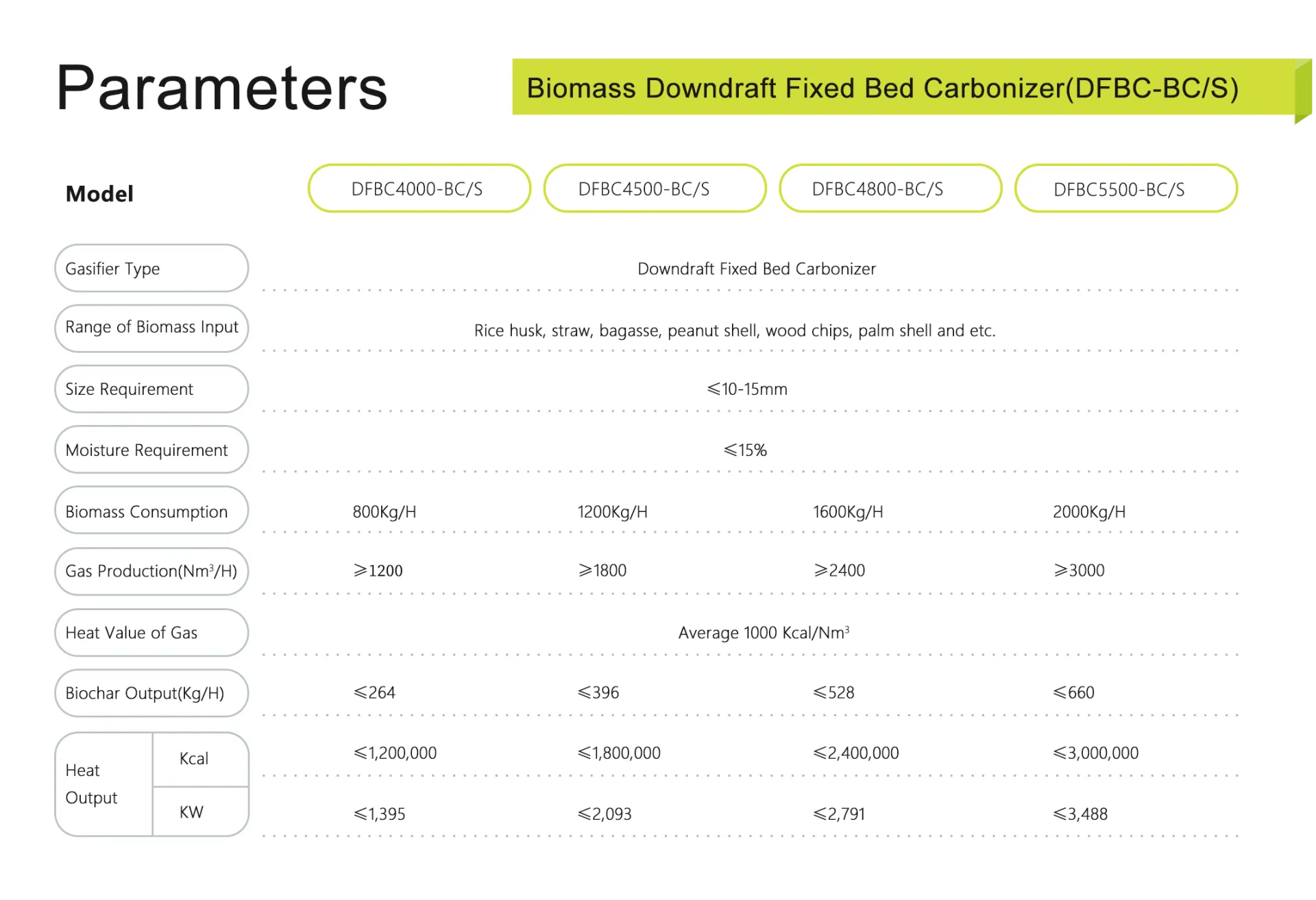

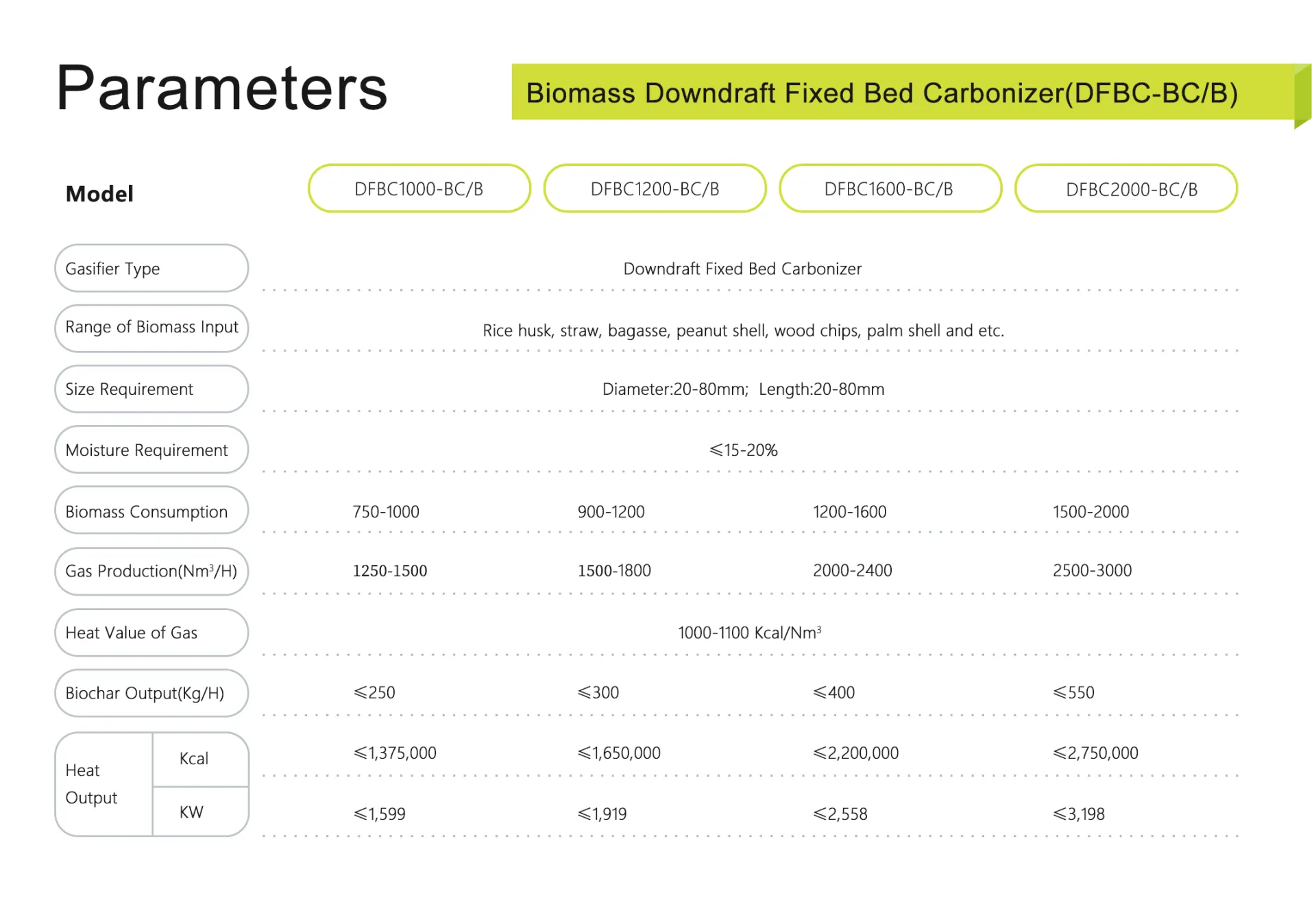

5 Equipment Models Available

Capacity: 300 kg/hr to 5 MT/hr ,

.jpg)