Biomass Torrefaction & Carbonization Systems | Pyrogreen

Nov 04, 2025

Biomass Torrefaction & Carbonization Systems | Pyrogreen

Pyrogreen's advanced biomass torrefaction technology and carbonization solutions transform waste biomass into high-value biochar and renewable fuels. Our torrefaction equipment is engineered for measurable carbon removal and sustainable revenue generation.

Technology Overview: Precision-Controlled Thermal Conversion

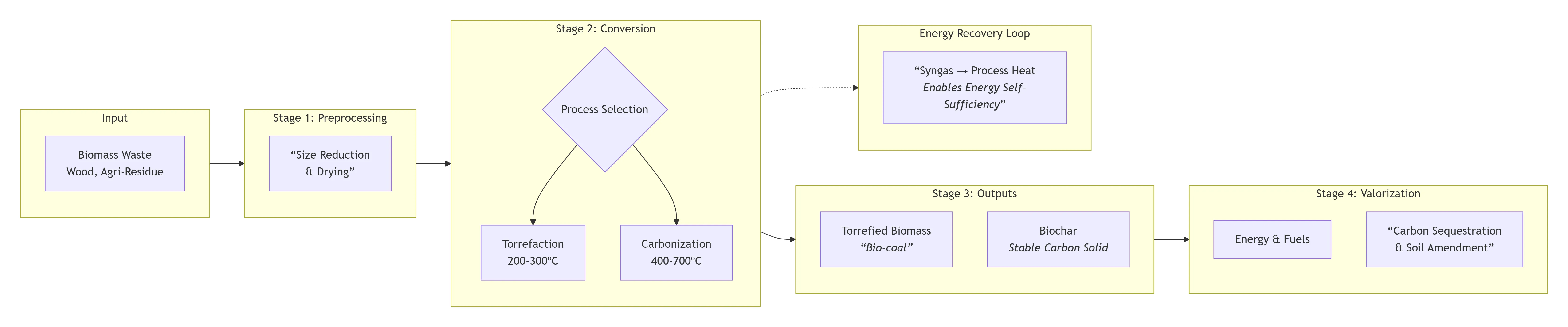

The biomass torrefaction process and biomass carbonization process represent optimized points on the thermal spectrum, delivering distinct products for specific markets.

Process Differentiation

Biomass Torrefaction Process (200-300°C): Produces energy-dense "bio-coal" ideal for co-firing, with superior grindability and hydrophobic properties.

Biomass Carbonization Process (400-700°C): Generates stable, porous biochar for agricultural, industrial, and carbon sequestration applications.

Integrated System Architecture

Our biomass pyrolysis system designs employ a staged approach, centered on the core torrefaction reactor or carbonization unit:

The efficiency of our torrefaction plant design is proven through its energy recovery loop, where process syngas provides operational energy self-sufficiency.

Engineered Torrefaction and Carbonization Equipment

1. Screw Conveyor Carbonization/Torrefaction System

This torrefaction machine leverages a continuous-feed, fully enclosed design for precise control. As a hallmark of modern biomass torrefaction technology, it achieves no tar and liquid waste production, making it a clean pyrolysis equipment solution. Its modular concept is a key advantage for scalable torrefaction plant deployment.

2. Rotary Kiln Carbonization/Torrefaction System

This robust torrefaction equipment is ideal for heterogeneous feedstocks. The rotating torrefaction reactor ensures uniform thermal treatment, leading to high biochar quality and quantity production. This system is a workhorse for large-scale biomass torrefaction plant operations.

3. Updraft & Downdraft Fixed Bed Carbonization Systems

These systems represent a reliable class of carbonization equipment. The downdraft fixed bed carbonization system excels in producing clean syngas, while the updraft fixed bed carbonization system offers simplicity and robustness for specific wood torrefaction equipment applications.

Investment Analysis: Evaluating Torrefaction Machine Price and Plant Cost

A thorough evaluation of torrefaction machine price and total torrefaction plant cost must consider the long-term value creation of integrated biomass torrefaction technology.

Capital & Operational Economics

Torrefaction Equipment Value: Initial torrefaction machine price is offset by low operating costs and energy self-sufficiency.

Torrefaction Plant Cost Efficiency: The modular concept of our systems allows for phased investment, optimizing capital allocation for your torrefaction plant.

Revenue Diversification: Our biomass pyrolysis system creates multiple streams from biochar, fuels, and waste processing fees.

Environmental Performance: Verifiable Carbon Impact

The biomass torrefaction process and carbonization solutions are quantifiable carbon-negative technologies.

Carbon Sequestration: Biochar from our carbonization equipment securely stores carbon for centuries.

Emission Performance: Our torrefaction equipment achieves extremely low NOx, CO, and particle emission, exceeding stringent standards.

Implementation Pathway

From Feasibility to Operation

We guide clients from initial biomass carbonization solutions assessment through to commissioning of the full torrefaction plant, ensuring a seamless integration of the biomass pyrolysis system into your operations.

Conclusion: Partnering for a Carbon-Negative Future

Pyrogreen delivers industrial-scale carbonization solutions through precision-engineered torrefaction and carbonization equipment. We provide more than a torrefaction machine; we deliver a complete biomass torrefaction plant solution that transforms liabilities into assets.